Технические науки / 12. АСУ на производстве

Shchepetov A.V., Еchina E.V.

Novokuznetsk branch-institute of FEI HPE "Kemerovo State

University",

Russia, Novokuznetsk

Modernization

of the information system of weighing

and

acceptance of cargo at the site of railway rolling

The

metallurgical industry is a basic sector in the economy of Kuzbass, which

accounts for 43% of the total volume of industrial production, 23% of

industrial and production assets. Mining and Metallurgical Complex includes

more than 150 large and medium-sized enterprises and organizations employing

approximately 70,000 people. Its services employ tens of specialized construction,

repair, energy, transport, mine rescue organizations and research-design

institutes. Due to the rapidly developing information technologies, new

possibilities for controlling metallurgical enterprises appear.

No one

industry can do without accurate information about the weight of raw materials,

finished products and components. Weighing economy is a necessary part of the

technological chain of almost any enterprise. Any production of

industrial-scale, without accurate data on finished product, supply and others,

would harm its system of accounting and control.

From the

1990s to the present day at the metallurgical enterprises of the South Kuzbass,

more and more are being introduced information systems, automated workplaces

(AWP), automated control systems, which allows to simplify the control of

technological processes, systems of weighing, etc.

One of the

main problems of information technology on one of the metallurgical enterprises

of the Kemerovo region - accounting discrepancy of data with real data that

come from the automated control systems of technological processes (ACSTP).

The

perspective of a question can be summarized in the following points:

from time to

time at the enterprise arises the need to make adjustments of the data on the

weights, but at the request of the security service it was forbidden personnel

site of the rail rolling to make any changes to the database about the weight

of the cargo without appropriate documents (applications and explanations);

the

enterprise's management has been decided to delegate responsibilities for the

adjustment of weight data of the master plot of weighing and acceptance of the

cargo;

the necessity

has appeared to create a software product, which will allow the master to adjust

information collected in a database; corrections of information were not

displayed anywhere by workers, so keeping track of data changes could not manage;

sending data

from computers of weighers is carried out through a program created with the

help of Visual Basic, Access database

with a common base of Oracle, which, in turn, is available to the corporate

network for personnel work, but the existing program often gave failures,

causing the need to call service employees at the place of breakage.

The purpose

of the done work was the improving of the automated workplace of the plot

weighing and acceptance of the cargo site of the railway rolling through the

creation of the application software.

In the course

of the research the subject area was studied, that concerns the weight economy

of the enterprise, disadvantages of the existing information system of

adjustment of the weight of the data and their transfer to a shared server were

considered, own development of software for solving the above problems was offered.

Often such

situation meets at the enterprise: when weighing of the raw materials scales

show 63 tons of ore, and the invoice from the supplier comes to 62 tons. At

this point a question arises - what to do with a ton of difference? Suppliers

are wrong too often, sometimes weighing equipment sometimes faults for reasons

of lack of repair or weather conditions, weighers can be wrong, when weighing,

etc. The plant consumes about 1400 trucks of various resources in the day. The

final difference, in the event of discrepancy of real data that have fallen

into the accounting system, can have a significant impact on the performance of

the whole enterprise and lead to significant losses. The process of adjustment

of data takes up too much time. So the software has been created for the master

plot of weighing and acceptance of the cargo, which has the authority to make

adjustments weight data.

The data from

the ACSTP, weighing systems, accounting systems, material balance are gathered

by the information system. There commercial information also falls, for

example, on the shipping of products. The system is a global system, providing

information view. Information from computers of weighers is recorded from the

weights into the database with the control of MOAccess 2007, and only from

there it is passed to the server of the Office of Information Technology (OIT)

to a database managed by Oracle to access the corporate network. The transfer

of the data, in turn, was carried out by the program "Data

Transmission", created with the help of Visual Basic at the enterprise.

Taking the

above into account, application software was developed for two types of users:

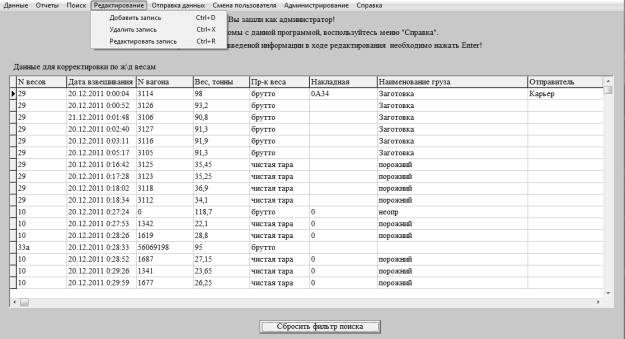

for

administrator (i.e. for the master of a site) with the functions of weight

data, adjusting them, save the changes made to the base (corrections, add,

delete entries), reporting on passing the traffic flows for different periods,

as well as shipments of outdated data in the archive in order to avoid overload

of the system (fig. 1);

Figure 1 – The

window for the work of the manager (administrator)

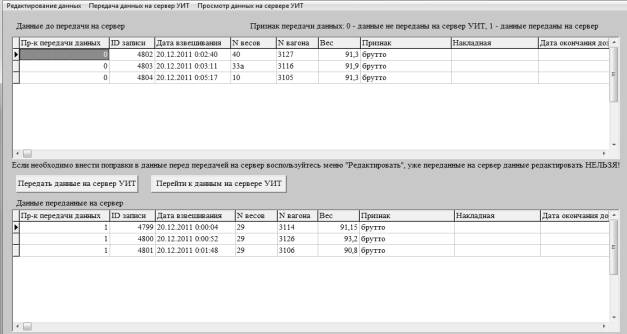

for user

(i.e. for the receiving deliverer or the weigher) with the functions of viewing

the weight data, archive data, reporting on passing the traffic flows, sending

data to the server (fig. 2).

Figure 2 – The

window for the work of the weigher (user)

The developed

software has allowed solving the tasks of the correction of weight data of the

site of railway rolling and transferring data from computers of weighers to the

common network of the enterprise, thereby speed up the process of making and

sending of cargoes at the enterprise.