Aminov R. Z., Bayramov

A. N.

Department of Energy Problems of Saratov Scientific

Center

of Russian Academy of Sciences

Investigation of the

efficiency of Atomic power station in to integrate with energy complex with

hydrogen fuel

Proposed a scheme of the energy

complex with hydrogen fuel in to

integrate with atomic power station. Evaluated technical and economic

parameters of the hydrogen cycle depending on proportion used by off-peak power

NPP power unit. Determined by the competitive efficiency of atomic power

station with energy complex with hydrogen fuel

in comparison with the pumped storage station.

Strategy

for the Development of Atomic Energy of Russia envisages a substantial increase

in the share of atomic power station in power systems of European part of

Russia. In this connection, issues of improving the safety and effectiveness of

their work are especially actual.

The

planned high growth rates of the atomic power station leads to the problem of providing

base-electrical-load during the period of nighttime lows in the electricity

grid. Traditionally, to align of base-electrical-load of atomic power station supposed

to use pumped storage station, but since their construction requires special

environmental conditions and, as a rule, the near the NPP is not possible, this

suggests that they be charging from the grid. In this case, the night the electricity tariff

significantly exceeds the self cost of electrical energy of atomic power station,

which significantly affects the cost of peak electricity produced by pumped

storage plant. In this connection, a need to develop alternative technologies

of accumulation of electricity. One such technology may be the use of energy

complex with hydrogen fuel, the advantage is its location near a atomic power station

with the possibility of charging at self cost of electrical energy. At night,

carried out produce of hydrogen and oxygen by electrolysis of water and their

accumulation in the storage system. In the hours of peak electrical load,

hydrogen and oxygen are used in a cycle of atomic power station to increase its

electric power.

Thus,

development of efficient and reliable energy complex with hydrogen fuel is

actual.

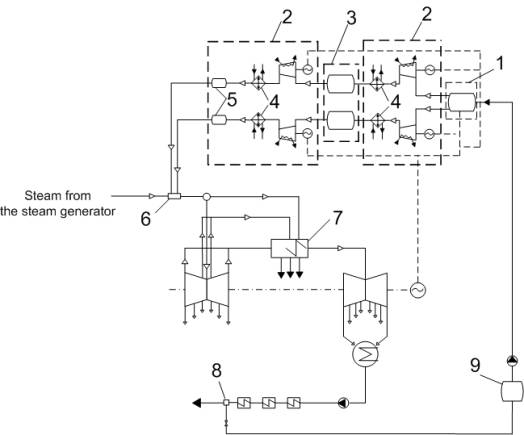

Energy

complex with hydrogen fuel includes a water electrolysis system of high power

and pressure, gas compression system before and after the storage capacity, a

system of storage of hydrogen and oxygen on the basis of metallic storage

capacity (in Fig. 1 for example, the steam turbine K-1000-60/1500).

Fig.1 Schematic Diagram Of

The Integration Of Atomic Power Station With Energy Complex With Hydrogen Fuel:

1 water electrolysis system; 2 a system of

compressing hydrogen and oxygen; 3 system of storage of hydrogen and oxygen

on the basis of metallic storage capacity; 4 final cooling heat exchanger; 5

intermediate storage capacity of hydrogen and oxygen; 6 place of the

steam-hydrogen overheat; 7 separator-steam superheater; 8 plot for filing

of the condensate to the system of water electrolysis; 9 condensate capacity tank

for the electrolysis

During

the peak load in the power grid, hydrogen and oxygen from storage tanks come in

compression to a working pressure of fresh steam at the inlet to the to a head

of steam turbine. Electricity for the booster compressors is assumed to consume

from the nuclear power plant. Intermediate tank of hydrogen and oxygen can

smooth out fluctuations in the supply of gases in a plot steam-hydrogen

overheating.

The

location of the energy complex with hydrogen fuel can be carried out at a

separate area at an acceptable distance about nuclear power plant. This task in

this paper is not considered, but will be developed in future.

New

feature of the scheme of the hydrogen cycle is to use a booster

compressors after the storage tanks. This

eliminates the accumulating hydrogen and oxygen at pressures much higher than

operating pressure steam of steam turbine (6 MPa in this example).

Effective

use of hydrogen fuel in the cycle of nuclear power plants to produce additional

(peak) power can be carried out by steam-hydrogen overheating of fresh steam.

In this case the steam-hydrogen overheat can be carried out by a two-step

oxidation of hydrogen with oxygen [1, 2, 3]. In this case it is possible to

eliminate the use of the component cooling. This allows the most efficient use

of summing up the heat of hydrogen fuel. It is assumed that high-temperature

steam formed in the system cooled by fresh steam and not moving on any

connecting pipeline.

The use

of steam-hydrogen overheat on the existing turbines is possible only within

their power to more nominal. For NPP turbines made to existing

projects, the possibility of increasing capacity within a 100 MW.

In

place of the steam-hydrogen overheat high-temperature steam is mixed with fresh

steam of turbine NPP. This can

significantly increase the temperature of the working steam before the steam

turbine. It may be necessary to upgrade equipment of steam turbine in the first

place, the cylinder pressure, and electrical parts. As a result steam-hydrogen

overheating leads to the production of additional peak power. At the same time

the work of the reactor and steam generators remain unchanged.

Return

of the added part of the working steam of the cycle of the atomic power station

as a result of steam-hydrogen overheat in the process of electrolysis, it is

advisable in a heated condensate (after a low-pressure heaters). Thus, it will

enhance the efficiency of water electrolysis process in its implementation of

the pressure [4, 6]. In such a closed loop operating costs at the chemically

treated water can be ignored.

Justification Use Electrolysis Increased Power To

Produce Hydrogen And Oxygen

Most

effectively to carry out the process of electrolysis under pressure [4-8]. For

example, we know that it is expedient to increase the system pressure

electrolysis from atmospheric to 1 - 5 MPa, and the process temperature is 120

160 °C [7].

The

current electrolysis plant (Russian or foreign) have low power. Maximum power

of currently available electrolyzers is 3 MW. Production in Russia,

Chemical Engineering Company in the city of Yekaterinburg. Therefore, for

large-scale production of hydrogen and oxygen during the night off-peak power

consumption atomic power station they are needed in large quantities (up to a

thousand or more). This requires considerable space, numerous attendants, as

well as complicating the control of production.

In this

connection it is necessary to create electrolysis plant increased power, with

the possibility of operating with frequent starts and stops without reducing

the service life [1]. Thus, based on [1], the power of the electrolysis plant

of energy complex with hydrogen fuel adopted by 50 MW.

Thus,

based on [1], the power of the electrolyzers of energy complex with hydrogen

fuel adopted by 50 MW.

Justification And Assessment Of Cost Of The Storage Of

Hydrogen And Oxygen In A Daily Cycle

Feasibility

of a particular method of storing hydrogen in the long run, will be determined

by its cost, weight and volume indices, power and performance characteristics (for

example, the dynamics of accumulation and output of hydrogen).

A

detailed comparative analysis of alternatives for hydrogen storage was carried

out by many authors. Among the recommendations regarding the use of common

methods of storing hydrogen in a variety of applications, there are underground

storage tanks, both natural and man-made, high-pressure composite cylinders,

organic hydrides, metal hydrides, cryogenic vessels, both high and low pressure

[9].

Production

of hydrogen and oxygen in the off-peak nighttime periods of electrical load may

require large-scale storage. Specificity of storage of hydrogen and oxygen

under these conditions is associated with daily accumulation and output from

the storage system.

Underground storage method of large quantities of hydrogen is the most

preferred [9, 10]. However, in the

daily cycle of the application of underground storage creates certain technical

difficulties. When the period of storage of hydrogen and oxygen can be from

several hours to several days, is most suitable on the ground (underground)

storage in a compressed form in special by metal storage capacity (cylindrical

or spherical gas holders) [11, 12].

As the storage system of hydrogen and oxygen in this case are

considered on the ground cylindrical storage

capacity of 100, 400, 800 m3 with spherical bottoms, in which hydrogen is

pressurized [11].

In table. 1 shows the results of calculations of the specific

investments in storage capacity of hydrogen and oxygen taking into account

production, assembly and automation.

Table 1 Specific Investment

In Storage Capacity Of Hydrogen

And Oxygen Volume Of 100, 400

and 800 m3

|

Pressure Storage, MPΰ |

Specific Investments In Storage Capacity This Volume, dollar/m3 |

||

|

100

m3 |

400

m3 |

800

m3 |

|

|

2,2 |

320 |

350 |

350 |

|

4,2 |

650 |

600 |

590 |

|

6,4 |

950 |

910 |

850 |

Lowering

of the specific investments in capacity with an increase in its volume at a

pressure of accumulating 4.2 and 6.4 MPa due to a decrease in the estimated

value of the resistance of steel with an increase in its thickness (due to the

increasing pressures on the storage capacity walls) [13]. This value, depending

on the thickness of steel, has an impact on the cost of production. In the case

of accumulation of 2.2 MPa pressure with an increase in capacitance value of

the calculated resistance of steel is higher than in versions 4.2 and

accumulation of 6,4 MPa. Therefore, specific investments in storage capacity are

increase.

The

results of calculation of the specific investments in storage capacity of

volume of 100, 400, 800 m3 deposited per unit mass of hydrogen and oxygen made from steel 09G2S,

in the temperature of storage of hydrogen and oxygen of 7 °C to 27 °C

are shown in Fig. 2, 3.

t = 7°C t = 27°C a![]()

![]()

t = 7°C t = 27°C b

![]()

![]()

t = 27°C t = 7°C c

![]()

![]()

Fig. 2 The Dependence

Of The Specific Capital Investments Per Unit Mass Of Hydrogen Stored In Storage

Capacity Of Volume: a 100 m3, b 400 m3, c 800 m3

t = 27°C t = 7°C a

![]()

![]()

t = 27°C t = 7°C b

![]()

![]()

t = 27°C t = 7°C c

![]()

![]()

Fig. 3 The Dependence

Of The Specific Capital Investments Per Unit Mass Of Oxygen Stored In Storage

Capacity Of Volume: a 100 m3, b 400 m3, c 800 m3

From

these data presented in Fig. 4 and 5 shows that the storage of hydrogen and

oxygen more efficiently use a larger storage capacity (400-800 m3)

and in the pressure range 4 6.5 MPa. In the scheme of the energy complex with

hydrogen fuel (Fug.1) a pressure in the storage system is accepted 4 MPa.

This

method of storing hydrogen in storage capacity is competitive in terms of

specific power inputs and value indicators in comparison with other methods

(Fig.4, 5).

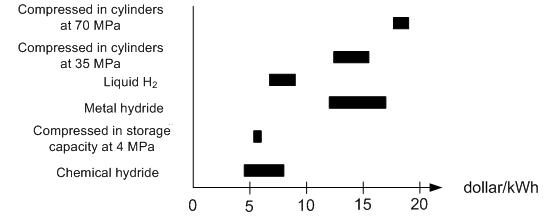

Fig.4 Competitive

Energy Costs For The Implementation Of Ways To Store Hydrogen In By Metal

Storage Capacity

Fig.5 Competitive

Cost Performance Of Hydrogen Storage In By Metal Storage Capacity

For

example, at a pressure of 4 MPa and the storage temperature of 27 °C

range of specific investment in storage capacity with the increase of its

volume from 100 to 800 m3 of 205 185 dollar/kg H2

or 6.0 5.5 dollar/kWh, respectively. From a comparison shows that the storage

of hydrogen in a compressed form in storage capacity of cylindrical type is

competitive with the way the use of chemical hydrides. At the same time, such

methods of storing hydrogen as a metal hydride, cryogenic and compressed in

cylinders under high pressure are uncompetitive.

Evaluation Of Technical And Economic Parameters Of The

Energy Complex With Hydrogen Fuel

Table 2

presents some technical and economic parameters of the energy complex with hydrogen

fuel at nuclear power plant.

Table 2 Some Technical

And Economic Parameters Of The Energy Complex With Hydrogen Fuel

|

|

Use power

for the production of hydrogen and oxygen (ΜW) / temperature of overheated steam at the

turbine inlet (°Ρ) |

||

|

100 / 290 |

500 / 376 |

1000 / 503 |

|

|

Investment

in energy complex with hydrogen fuel, thousand dollars/kW

(peak power) |

0,3 |

0,93 |

0,89 |

|

The

volume (mass) production of hydrogen, thousand normal m3/day

(thousand kg/day) |

126,5 (11,4) |

632,5 (57,0) |

1270 (114) |

|

The

volume (mass) production of oxygen, thousand normal m3/day (thousand kg/day) |

63,24 (90) |

316 (460) |

635 (900) |

|

Peak power

(electric power) ΐέΡ,

kW (kWh/day) |

54500 (272400) |

301000 (1505000) |

610800 (3054000) |

|

Effective

use of hydrogen fuel in the cycle NPP |

71,8 |

80,0 |

80,6 |

|

The

efficiency of the use of off-peak

electricity NPP

|

38,9 |

43,5 |

43,6 |

|

Efficiency

of NPP gross/net, % |

34,18/32,37 |

37,37/35,53 |

40,62/38,71 |

Thus,

by using steam-hydrogen overheat increase the efficiency of power block of

atomic power station may amount to gross 0.9-7.3%, and 0.7-7.0% net.

Competitive Efficiency Of Energy Complex With Hydrogen

Fuel And The Pumped Storage Plant

Comparison

of atomic power station with energy complex with hydrogen fuel and the pumped

storage plant to production of peak electricity (capacity) was carried out with

the equal consumption of the off-peak electricity of the night time. Night

off-peak period electrical load is

assumed to be equal 7 h/day number of hours of use energy complex with hydrogen

fuel and the pumped storage plant for the production of peak power (capacity)

is assumed to be equal to 5 h/day. Number of hours of use for a NPP power unit

in the year is assumed to be equal to 7000 h / year. The tariff for peak

electricity is assumed to be equal. Comparisons carried out to the depending on

proportion used by off-peak power NPP power unit. Horizon calculation is

assumed to be equal 25 years, discount rate constant on the horizon and equal

to 0.1. Were taken into account methodical recommendations on evaluation of

investment projects. The options were reduced to equal the energy effect [2].

The advantage of the energy complex with

hydrogen fuel is the ability of its location near the atomic power station with

the consumption of electricity at the its self cost. It is virtually impossible in the case use of pumped storage plant.

In this case, pumped storage plant consumes electricity from the grid on tariff

that exceeds the cost of electricity in two to three times. In addition, the

location of the energy complex with hydrogen fuel near the atomic power station

reduces the electricity losses during transmission.

In Fig.

8 is shown net discounting profit, depending on the use of off-peak power of

NPP power unit, and various ratios of the tariff for consumption of electricity

from grid and from atomic power station: ξ = 1, 2, 3.

Fig. 8 Net Discounting

Profit Of Energy Complex With Hydrogen Fuel And Pumped Storage Plant: 1 energy

complex with hydrogen fuel; 2-4 pumped storage plant (k = 1000 dollars/kWh,

ξ = 1, 2, 3); 5-7 pumped storage plant (k = 1500 dollars/kWh,

ξ = 1, 2, 3)

The

most effective option is the pumped storage plant with specific investments not

exceeding 1000 dollars/kW. Consumption

of electricity from atomic power station at self cost (ξ = 1, line 2). But

using off-peak power of 100 MW is more efficient variant of the energy complex

with hydrogen fuel.

Variants

for using pumped storage plant with k = 1000 dollars/kW, ξ = 2 and for k =

1500 dollars/kW, ξ = 1 are competitive with energy complex with

hydrogen fuel (lines 3 and 5, respectively).

Variants

for using pumped storage plant with k = 1000 dollars/kW, ξ = 3 (line 4)

and for k = 1500 dollars/kW, ξ > 1 (line 6 and 7) are uncompetitive

with energy complex with hydrogen fuel.

The

index income and payback period of the energy complex with hydrogen fuel is estimated:

when using

off-peak power 100 MW of NPP power unit: index income 2,6 dollar/dollar, payback

period ≈ 9 year;

when using

off-peak power 500, 800, 1000 MW of NPP power unit: index income 2 dollar/dollar,

payback period ≈ 12-13 years.

Conclusion

The set

of technical challenges and risks in the construction of pumped storage

suggests their location is not near a atomic power station. This leads to the

consumption of electricity during the night time at tarrif of electricity

greater than the self-cost electricity of atomic power station in more than 2 -

3 times. This significantly increases the competitiveness of hydrogen cycle on

atomic power station even at a more lower efficiency of production of

electricity in peak times.

The

most effective option is the pumped storage plant with specific investments not

exceeding 1000 dollars/kW. Consumption

of electricity from atomic power station at self cost. But using off-peak power of 100 MW is more

efficient variant of the energy complex with hydrogen fuel.

Competitiveness

of the pumped storage plant is markedly reduced when specific investments over

$ 1,000 / kW and the tariff of electricity is 2-3 times higher than the self

cost of electricity of atomic power station.

These

results indicate the presence of zones of competitive efficiency of atomic power

station with energy complex with hydrogen fuel at compare with pumped storage

plant.

These

developments allow to take into account the specific conditions of construction

of power plants with the accumulation of electricity at comparing their

efficiency.

Sources Used

1.

Aminov R. Z. Evaluating The Effectiveness Of The Hydrogen Cycle Based On Off-Peak

Electricity Of Atomic Power Station / R. Z. Aminov, A. N. Bayramov,

O. V. Shatskova // Thermal Engineering. 2009. Ή11. P.41-45.

2.

Aminov R. Z. System Efficiency Of The Hydrogen Cycle, Based On Off-Peak Electricity

Of Atomic Power Station / R. Z. Aminov, A. N. Bayramov // News of the Russian Academy of Sciences. Power

Engineering. 2011. Ή4. P.52-61.

3. Patent

Ή2427048. Russian Federation. The System Of Burning Hydrogen For Steam-Hydrogen

Overheat Of Fresh Steam In A Cycle Of Atomic

Power Station / Aminov R. Z., Bayramov A. N.; Applicants and Patent

Owners: Aminov R. Z., Bayramov A. N. Ή 2009117039/06; Stated 04.05.2009; Published 20.08.2011. 8 p.:

Illustrations.

4. Yakimenko

L. M. Electrolysis Of Water / L. M. Yakimenko, I. D. Modylevskaya,

Z. A. Tkachek. Moscow.: Chemistry, 1970. 263 p.

5. Yakimenko

L. M. Electrode materials in Applied Electrochemistry / L. M. Yakimenko.

Moscow.: Chemistry, 1977. 264 p.

6.

Yakimenko

L. M. Production Of Hydrogen, Oxygen,

Chlorine And Alkali / L. M. Yakimenko. Moscow.: Chemistry, 1981.

279 p.

7. Shpil'rain

E. E. Introduction To Hydrogen Energy / E. E. Shpil'rain, S. P. Malyshenko,

G. G. Kuleshov. Moscow: Publishers Energoatom, 1984. 264 p.

8.

Aminov R. Z. The Efficiency Of Hydrogen Production Based On Modern Technology

/ R.Z. Aminov, A. N. Bayramov // News Of The Russian Academy Of

Sciences. Power Engineering. 2009. Ή1. P.128-137.

9. Yartys

V. A. A Survey Of Methods For Hydrogen Storage / V. A. Yartys, M. V. Lototskii. Institute for

Problems of Materials Science of Ukraine. 2003.

10. Malyshenko S. P.

Some thermodynamic and technical and economic aspects of hydrogen as an energy

carrier in power engineering / S. P. Malyshenko, O. V. Nazarova,

U. A. Sarum // Atomic-Hydrogen Power Engineering And Technology. Moscow:

Publishers Energoatom, 1986. Issue

Ή 7. P. 105-126.

11.

Aminov R. Z. Evaluation of specific investments in cylindrical storage

capacity for the storage of gaseous hydrogen / R. Z. Aminov,

A. N. Bayramov // News Of Higher Educational Institutions. Problems Of

Power Engineering. 2007. Ή 5-6. P. 69-77.

12. Cost of Storing and Transporting Hydrogen / National Renewable

Energy Laboratory of the U. S. Department of Energy. 1998. P. 52.

13. Takhtamyshev A. G.

Examples Of Calculation Of Steel Structures / A. G. Takhtamyshev. Moscow: Publishing

House Of Construction, 1978. 239p.