UDC 628.517.2:669

RESEARCH OF ACOUSTIC PROPERTIES OF CAST ALLOYS

E.B,Utepov, E.B.Ten, S.T. Kaldybaeva., (Almaty. KazNTU them. K.I. Satpaeva)

Noise is harmful not only to human health, but also the country's economy. Health workers - the wealth of the republic is an essential condition for the development of production and hence economic growth. So people who are employed work mental strength, made on the background noise of 70 dB is almost two times more errors than in silence. Efficiency engaged in mental work falls by about 60%, and physical - by 30% [1].

People now live in a constant environment of noise, as long as the

inevitable consequence of technological development. To-noise ratio can not

adapt. The need for silence was universal problem, over which serious thinking

in many countries.

For details of mining

equipment used foundry steels 20L, 30L, 45L, 55L (parts subject to impact

loads, details of cast-welded construction with a lot of welding, hull - 20L;

body reducers, couplings, pulleys, brackets, frame drilling machines - 30L ;

details of drill pipes, drill transmission bushings compressor, ratchet and

other important parts, which are requirements of high strength and high

resistance to wear - 45L, gears, wheels, gears, gear couplings mountain

industrial machines-50L).

The object of investigation casting alloys chosen as samples of standard

steels 20L, 30L, 45L, 55L, and the new fused (Table 1) doped with chromium,

silicon, manganese and nickel. To investigate the noise drills chosen alloy steel

30ÕÃÑÀ, 45HN, 18H2N4VA, 38HN3VA used for the manufacture of drill pipe and the

shell crown punch.

Table 1 - Chemical composition of alloys

|

Brand àlloys |

Chemical composition, wt% |

||||||||

|

Ñ |

Si |

Mn |

Cr |

Ni |

Cu |

S |

P |

Fe |

|

|

max |

|||||||||

|

20Ë |

0,17-0,25 |

0,20-0,52 |

0,35-0,90 |

0,20 |

0,30 |

0,30 |

0,05 |

0,05 |

rest |

|

30Ë |

0,27-0,35 |

0,40-0,90 |

|||||||

|

45Ë |

0,42-0,50 |

||||||||

|

55Ë |

0,52-0,60 |

||||||||

|

ÑÊ-1 |

0,14-0,20 |

0,44 |

0,8 |

0,84 |

0,75 |

0,30 |

0,05 |

0,05 |

|

|

ÑÊ-2 |

0,14-0,21 |

0,48 |

0,71 |

0,68 |

0,66 |

0,30 |

0,05 |

0,05 |

|

|

ÑÊ-3 |

0,38-0,42 |

0,50 |

0,64 |

0,81 |

0,79 |

0,30 |

0,05 |

0,05 |

|

|

ÑÊ-4 |

0,45-0,52 |

0,51 |

0,66 |

0,77 |

0,91 |

0,30 |

0,05 |

0,05 |

|

The acoustic (sound level, sound pressure level) characteristics of the

alloys.

For the preparation of new damping alloys as the object of study were selected

structural steel foundries. Principles of alloying agent in the based on the

study of phase diagrams of Fe-C, Fe-Cr, Fe-Mn, Fe-Si and Fe-Ni. Chromium,

silicon and manganese are among the most frequently used special alloying

elements. Additions of alloying elements varied in the following ranges:

chromium from 0.68 to 0.84%, manganese from 0.64% to 0.8%, silicon 0.44% to

0.51% nickel from 0.66 to 0 91%. Carbonaceous additives served synthetic iron

with carbon content 3.9%. Choice of chrome, manganese, silicon and nickel as

alloying elements is explained as follows.

Smelting experimental alloys produced in the high-frequency induction furnace LPZ-1-67. Melting point t = 17000S. Power furnace N = 70 kW. When the work was used graphite crucible. The main metallic burdening the material used in Article 3. Doping produced 98% metallic manganese, 75% ferrosilicon, ferrochrome 60%, and 99,98% of metallic nickel. Carbonaceous additives served as synthetic iron containing 3.9% carbon. Melted metal is cast into molds size 210h210h115 mm. The ingots were hot forged technology: heating up 11000S, endurance 0.5 hours and forging with intermediate heating to 11000S. Normalization mode - heating up the AC3 +50 ° C, holding 1 h and cooling in air. Tempering was carried out by the regime: heating to AC3 +50 ° C, holding 0.5 h, cooling in water. Heating was carried out in quartz ampoules (vacuum about 10-3 atm.) Muffle furnace. Double annealing was carried out by the regime: heat to 920-9700S, endurance 1.5 hours, slow cooling. Samples for the study of acoustic characteristics of the cut from forged bars. The surfaces of wafers polished on a 5-th class of cleanliness. Deviations from the dimensions do not exceed 0,1 mm. Smelting, heat treatment and machining of all samples were carried out on a single technology at one and the same hardware. All samples are made in the form of a plate size 50h50h5 mm.

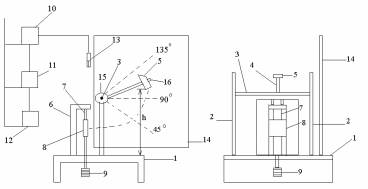

To investigate the collision noise tested steels and alloys (from the installation of NI Draiman 1968 to install "KazNTU-2006) was used to investigate the installation of impact sound" KazNTU-2007 "Figure 1.

Figure 1 - Installation

"KazNTU-2007" to investigate the noise of collisions metal flat

samples

Device 'KazNTU-2007 "includes the following elements: base (1); rack

(2) axis (3); rod projectile (4), drummer (5); bracket the sample (6); threads

mounting the sample (7 ) sample (8) weight (9) sound level meter (10)

oscilloscope (11) recorder (12), microphone (13); scale deviations impactor

(14), catch (15), nut (16).

The device

"KazNTU-2007" works as follows. Example 8 is attached to the

wreath taut thread 7 at the expense of relatively heavy in relation to sample

the goods (cargo weight 20 kg). Drummer 5 deviates from the lowest point at a

certain angle, which is defined as the scale of 14, and height h. Then the drummer

is released and it falls under its own weight and makes the collision with the

sample. Noise from the collision is measured accurately by a pulsed sound-level

meter "Octave-101A (10), the extinction curve of the shock process to

register an oscilloscope (11) and recorder (12). After the collision drummer

stops retainer (15), protecting against re-strike. Drummer (5) is a hammer with

the mass of the impactor 218, the firing pin is attached to the rod (4) with a

nut 16. Drummer (5) can make beats with varying strength, as there is an

opportunity to reject it under different angles from the equilibrium position.

We used four options: when the drummer was rejected by 30 º (h1 = 7 cm),

45 º (h2 = 10 cm), 75 º (h3 = 12 cm), 90 º (h4 = 17 cm).

Features zvukoizlucheniya

alloys was investigated after injection, normalization, annealing, quenching. After

casting, the samples were forged at t = 12000S.

When iron-casting alloy

alloying elements Si, Mn, Cr, Ni dissolved in the ferrite, thus, the atoms of

solute accumulated at the dislocation, as reduced elastic energy of the system.

At a temperature of 17000S, this temperature casting alloys are, engaged

in a process of redistribution of atoms of alloying elements, resulting in the

components of atoms occupy certain positions in the crystal lattice. In iron

alloys for casting formed metastable phase - cementite (Fe3C), the transition

to the stable phase is a violation of coherent communication grids and are

usually formed interface. After casting the metal is in the uneven condition

that causes Noise emissions in the collision. Microstructure of sample SC-2

after injection shows high fineness of cementite reticulated veins, and this

causes a high Noise emissions: UZFK-2 = 92dBA; UZD1000 = 57dB; UZD8000 = 90dB;

UZD16000 = 91dB.

LITERATURES

List of Sources

1. Vartanian I.A., Andreeva I.G., The noise of the benefit or detriment? / /

Nature. - 2001. - ¹ 3. - S.23-29.

2. Afanasiev R.F., Burmistrova O.V.,

- Occupational hazards for health workers: a guide. - M.: Trovant, 2003. - 236

pp.

3. Batesova F.K., Study of effect of

noise on hearing organ / / Journal of Scientific Papers "Adilet" ..- Almaty,

2008. - ¹ 4 (26). - Page 112-116.

4. Kondratyev I. Noise - this is

serious / / PCWEEK. - 2004. - ¹ 36. - S.287-290.