Kasymkhankyzy Aêerke

Master of the Kazakh-British Technical University

ANALYSIS

OF NEW IMPROVEMENT METHODS IN ENHANCEMENT OIL RECOVERY

Kazakh-British Technical University, Almaty, Kazakhstan

Review

This given

scientific article

is devoted to a new methods of oil discoveries on the

oil fields also the

author touched the aspect of enhanced oil recovery. You can find the

information regarding to description of a new

methods of oil recovery.

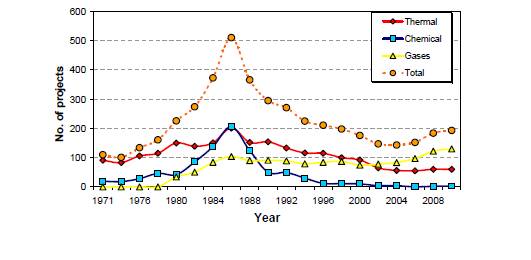

Improved Oil Recovery methods encompass Enhanced Oil

Recovery methods as well as new drilling and well technologies, intelligent

reservoir management and control, advanced reservoir monitoring techniques and

the application of different enhancements of primary and secondary recovery

processes. Chemical and thermal EOR projects have been used for a long time. (Figure

1) With the decline in oil discoveries during the last decades it is believed

that EOR technologies will play a key role to meet the energy demand in years

to come.

Figure1. Evolution

of EOR projects

One of

the new approved methods of EOR, termed ASPaM, has been developed and applied to a sector simulation

using some of the data from the South Slattery Field, Minnelusa A reservoir.

The new method, termed ASPaM, combines features of CO2 miscible

flooding with Alkaline – Surfactant – Polymer (ASP) flooding to produce an

enhanced WAG flood. A numerical pre – processor program had to be developed to

produce the required mixing zone properties of a CO2 front, which

are input to the CMG simulator, STARS. STARS is a chemical flood simulator, but

cannot accommodate the solvent model. The pre – processor calculates oil and

solvent properties based on the Todd – Longstaff procedure. Sensitivity

analysis showed this new method can give a much better recovery in comparison

to ASP or CO2 WAG flooding for different depositional environments.

Carbon dioxide has been used for enhanced oil recovery purposes since the 1950`s. Research on the use of CO2 for EOR continues with ever growing interest;

however, research concerning terrestrial sequestration of CO2 for environment purposes is relatively recent

. The CO2 can make up multi – contact and first contact miscibility

with oil at reasonable reservoir pressures while other miscible gases may not

reach this point for up to a couple of thousand psi more. WAG injection has

been applied with success in most field trials. The majority of the fields that

have been WAG flooded, are located in Canada and the U. S., but there are also

some fields in the former USSR. WaG injection has been employed since the

1960`s. Both miscible and immiscible injection have been used with many type of

gas . The terminology of miscible WAG, here, means the gas/oil miscibility may

be attained by multiple – contact.

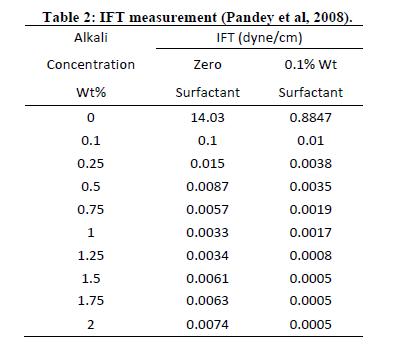

However, the WAG mobility control is not feasible in high or

medium viscosity oil; but it can be upgraded by using polymer to raise the

aqueous phase viscosity. Moreover the microscopic seep efficiency of the water

slug can be improved, if the interfacial tension(IFT) of the water/oil interface

is reduced. Atkaline-Surfactants are typical additives offering considerable

IFT reduction and consequently oil recovery improvement. The alkali converts

naphthalic acids in the crude oil to soaps. The combination of the soaps and a

suitably chosen injected surfactant reduced the interfacial tension to ultra

low values, where residual oil can be mobilized and oil trapping prevented and

it also reduces surfactant adsorption. Soaps are usually too lipophilic to

produce ultra low interfacial tension at reservoir conditions. Effective,

hydrophilic, injected surfactants can be injected in an alkaline-surfactant

process at salinities below their optimal salinities for oil recovery when used

absence of alkali.

This is investigated in application to the South Slattery Field in Wyoming, which has

been previously studied by Sheppy (1986), Towler (1991) and Gao and Towler

(2009).The South Slattery Field is a small Minnelusa field in the Poweder River

Basin with about 12 MMSTB oil in place. Different chemical flooding scenarios

have been investigated in addition to the new methodology, ASP alternating with

miscible CO2 (ASPaM) to improve recovery. Simulation of a sector of

the field was carried out using STARS, the advanced chemical flood simulator

from CMG. The historical water flood data has been matched and a chemical flood

model was investigated, which included accounting for chemical adsorption, the

residual resistance factor, surface tension as a function of the chemical

concentration and interpolation of relative permeability based on capillary

number and solvent concentration. Theoretically, the South Slattery Field

contains all of the conditions that CO2 flooding needs; depth,

temperature, oil gravity, porosity, permeability, etc. A continues CO2 injection

was used for comparison in the simulation research. The existence of a density

difference causes the CO2 to distribute unevenly. The CO2

flooding is a well recognized and tested enhanced oil recovery method because

the microscopic sweep efficiency of CO2 flooding is very high. The

CO2 dissolves easily in oil and reduces the oil viscosity, swells

the oil and extracts the light components.

Simulation

The advanced process chemical

flood simulator, STARS, was used to simulate the different chemical scenarios.

STARS has the ability to simulate all aspects of ASP flooding but it cannot

handle the miscible phase. No commercial simulator can accommodate both ASP and

miscible flooding. Consequently we calculated the oil and solvent properties

separately using the Tod and Longstaff (1972) method described below. The

following features were applied to simulate the required fluid-fluid and

fluid-rock interactions:

·

IFT reduction for up to two components.

·

Modification of the relative permeability from in capillary number.

·

Water viscosity increased by adding polymer.

·

Adsorption of chemical components.

·

Residual resistance factor due to adsorption.

·

Alteration of oil relative permeability owing to miscible flooding.

·

Oil density reduction due to swelling.

·

Reduction of oil viscosity by dissolution of CO2 in oil.

·

Alkaline consumption by carbonic acid.

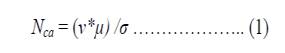

A key feature in the modeling

by STARS is: it interpolates different sets of relative permeability curves

based on capillary calculated by:

Where Nca is the capillary number ![]() is the velocity of

the fluid

is the velocity of

the fluid ![]() is viscosity

is viscosity ![]() is IFT between oleic

and aqueous phases.

is IFT between oleic

and aqueous phases.

The injection of chemicals

which decrease the IFT, increase the capillary number, which translates into a

change in relative permeability and a reduction in the residual oil saturation.

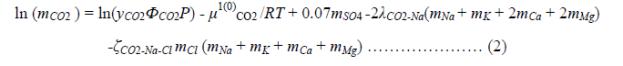

Here, eight components have

been used to properly model the complex IFT change, chemical adsorption,

miscible and dissolution phenomenons. The multiple alkaline consumption

reactions such as; formation brain, cation exchange, hydrogen ion exchange

reaction with petroleum acids, silica dissolution and kaolinite transformation

are lumped to the adsorption of alkaline to the rock, except for the reaction

with the carbonic acid. This helps us to keep accuracy, reduces simulation time

and numerical failure. The liquid-gas k-value tables were not required for dead

oil but are necessary for dissolution of carbon dioxide in aqueous solutions

containing Na, Ka, Ca, Mg, Cl and SO in

a wide temperature, pressure and ionic strength range.

He offered an equation to

calculate ![]() as a function of temperature and pressure.

as a function of temperature and pressure.

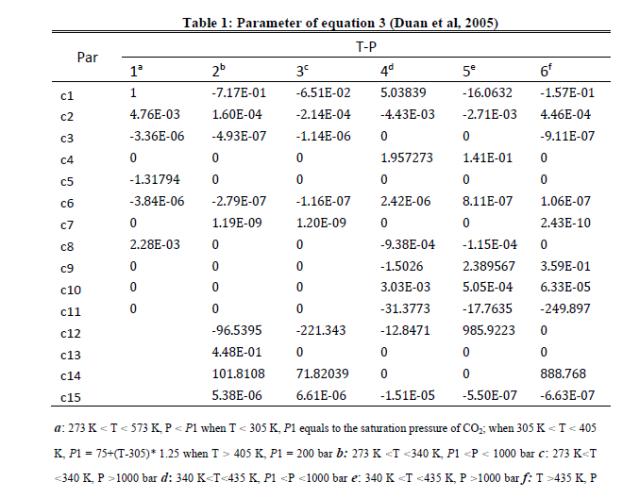

Table 1 lists the parameters

for equation 3. The dissolution of carbon dioxide is simulated in an authors’

program which produces an adequate feed for STARS.

In addition, the value of the

adsorption of polymer, alkaline, surfactant, accessible pore volume and

residual resistance factor were considered in the simulations. The relative

permeability shirts from purely immiscible to miscible as the capillary number

changes from Log=6 to 0,5.

The miscible displacement was

modeled in a separate program which produced the mixing zone data for

application in STARS and compares the result of this adapted STARS model with a

miscible simulator to make sure the required accuracy is achieved. The Todd and

Longstaff miscible model was used to calculate the four component version of

miscible displacement, which has already been proved for linear and radial

displacement.

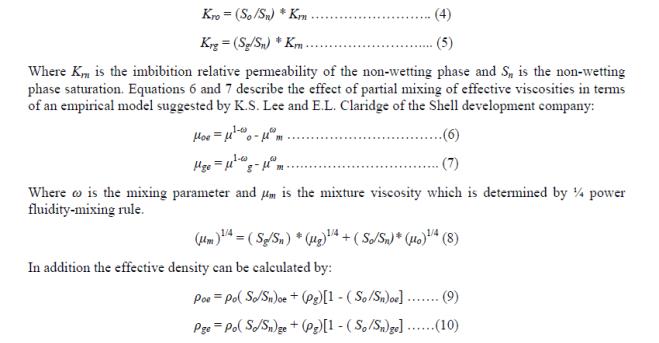

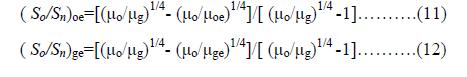

The following equations show

how the miscible zone properties were calculated. The relative perm abilities

of the miscible oil and gas might be determined as follows:

One of the interesting

features of ASPaM is that ASP and CO2 have a positive coupling

effect on each others displacement, especially the injectivity. However this

positive effect has not yet been formulated and can not be implemented in this

simulation. The carbon dioxide also has a positive effect on ASP flooding.

However, even in our simulation experiment, the infectivity in the linear

pattern was raised 14 times, due to some of the effects listed above. Figure 2

shows the water breakthrough can be postponed by more than 8% pore volume water

injection by the use of a 4% PV CO2 slug at the front of ASP, which

simply impies a piston like up to 55% for a 11% CO2 slug.

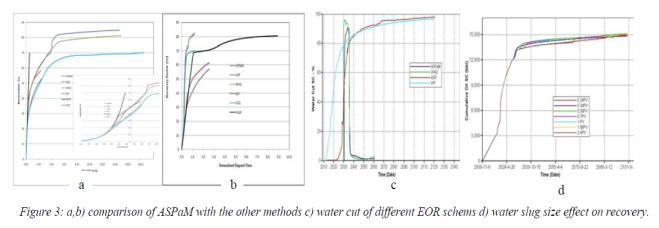

Numerous simulations have been

done to compare different EOR mechanisms: WAG, CO2, ASP,WF (water

flooding) and PASP (pure ASP flooding, no chase water) flooding against ASPaM

for different depositional environments. The sequence in ASPaM is 10% ASP

chased by water, preceded by a 10% CO2

slug size and finally followed by continuous CO2 injection.

While in the WAG that 10% ASP slug is substituted by water. The first

depositional system is an isotropic and homogenous reservoir. The recovery of

ASPaM is definitely more than the other schemes especially if time is

considered as shown in figure 3 a-b. Moreover ASPaM displays less water cut,

shown in figure 3c. Although PASP, which stands for pure ASP injection, shows

better recovery but is not economically feasible as the production life is too

long for the same recovery and cost of injection materials is very high.

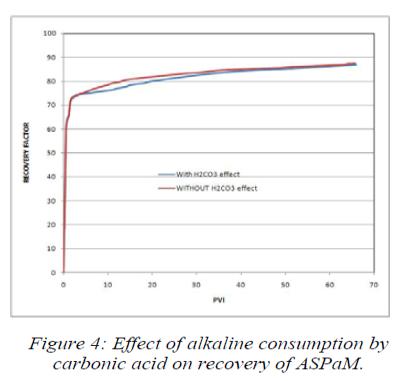

The alkaline consumption by carbonic

acid is an important issue but, since ASP and CO2 are being injected

alternatively, they don’t mix entirely and consequently the alkaline

consumption and gas/liquid mass transfer is expensive. Nevertheless this

complex system is simulated for a 2-D model, a diagonal of the sector model.

Figure 4 reveals no considerable change in ultimate recovery may happen if the

alkaline consumption were to be considered.

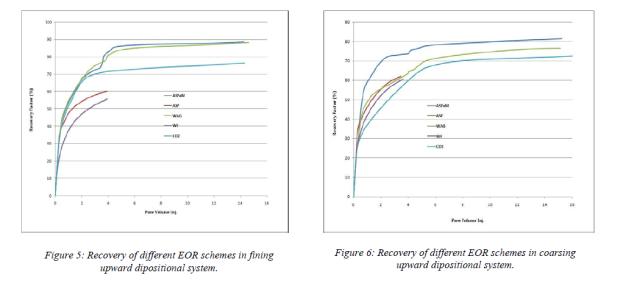

The recovery of ASPaM was

investgated in three heterogenous systems: coarsening upward, fining upward and

random-heterogeneity. The absolute permeability ratio of the overlaying stratas

in the coarsening upward system is 1/2/3 while in fining upward it is 3/2/1.

ASPaM in both fining upward and coarsening upward shows better recovery than ASP

and CO2 flooding alone while WAG almost has the same performance

with ASPaM in the fining upward deposition. However the recovery of both is

much more than the homogenouse system, figure5. The difference between the WAG

and ASPaM performance increases in coarsening upward in comparison with a

perfectly homogenous system and it is attributed to better micro sweep

efficiency of the bottom layer in ASPaM, while in WAG, the miscible

zone, CO2 front, is redirected to the upper layers, figure6, thus

the bottom layer displacement is immiscible. In the fining upward deposition,

the miscible zone of CO2 is redirected to bottom layers and improves

the recovery of WAG. Therefore the difference between them reduces.

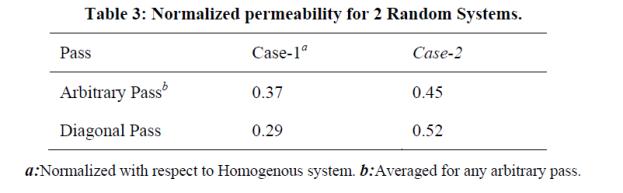

The random heterogeneity is

more complicated as the average permeability is changing with respect the path

chosen by the fluid. Two faces were chosen for this system, where the low

permeability faces has 7% of the high permeability faces permeability within

the same porosity. The stochastic program was written to calculate the average

permeability for any arbitrary pass, in addition to the average permeability in

the diagonal heterogeneity is the Lohrenz coefficient. But the Lohrenz

coefficient may not be the authors employed the described methodology, which is

based on flow direction, and represents better effect of permeability

heterogeneneity on fluid flow.

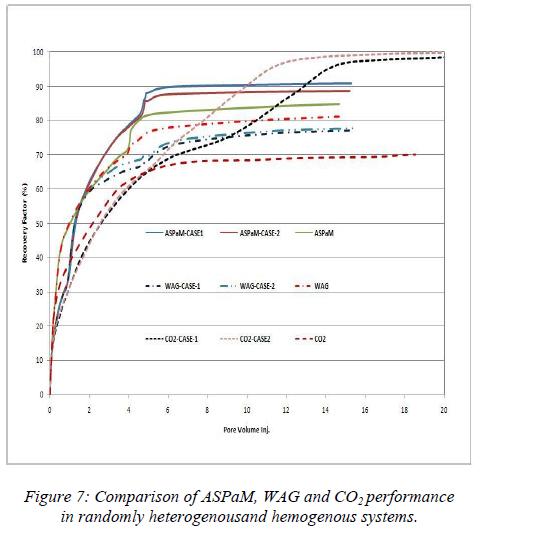

The results for ASPaM were

unexpected; the recovery of ASPaM increased in these random-wise

heterogeneities while the recovery of WAG reduced. Maps of the solvent

saturation in the random system, reveals its saturation in the deeper layers

increases, which improves the recovery. At the same time the saturation of the

trapped oil in the WAG process in heterogenous systems is increased, due to the

fact that it interferes with the positive effect of miscible displacement by CO2.

In fact heterogeneity has two effects; it increases the saturation of trapped

oil due to local trapping of the oil phase, which is a negative effect of

heterogeneity. In addition it may have a positive effect redirecting the

solvent zone to the non-swept area.

Based on this vision it was

expected that CO2 flooding would give better results since less oil

would be trapped by water. Figure 7 shows the recovery of ASPaM, WAG and CO2

for the homogenous and two randomly heterogeneouse systems. The recovery by CO2

flooding, in the heterogenous cases, shows a sudden rise after 4 PV injection

and overtakes the ASPaM after 9 PV for

Case-2, and for Case-1 it happens after another 3 PV of injection (12PV).

Conclusion:

This EOR scheme which is a combination of the two favorable commercial schemes,

ASP and CO2 flooding, shows a significant improvement in incremental

recovery. In addition it has less injectivity problem as the well has less

water cut. Furthermore, heterogeneity did not affect recovery significantly and

even may have a positive effect on recovery especially for a fining upward

deposition and a randomly heterogeneous system.