Figure 1: Workflows for

Control of Production Engineering

Sergey Larin, Alexey

Karpushin and Petr Sosnin

Sergey

Nikolaevich Larin, head of the complex production-engineering department of

Federal Research-and-Production Center ‘Research-and-Production Association

‘Mars’. [e-mail: larinmars@rambler.ru].

Alexey Nikolaevich

Karpushin, graduated from the Faculty of

Information systems and Technologies of Ulyanovsk State Technical University.

[e-mail: a.karpushin@ulstu.ru].

Petr Ivanovich Sosnin,

graduated from the Faculty of Radio-Engineering of Ulyanovsk Polytechnic Institute.

[e-mail: sosnin@ulstu.ru].

Abstract

The article presents and describes a set of tools for aspect-oriented

design of workflows in design and production engineering of pilot production.

An important advantage of the developed set of tools is a computer-aided

process for the development of design documents, tasks and interchange of data

(directive, reference and report documents) among design,

production-engineering services and cell-type systems. By now, the developed

system of pseudo-code programming tools for interface prototypes is a

time-proved system which has confirmed its stable operability in the mode of

real-production process.

Key words:

PSEUDO-CODE PROGRAMMING, INTERFACE PROTOTYPE, DYNAMIC COMPILATION.

The specific feature of pilot

instrument-making production whose products are to be embedded into

computer-aided systems (CAS), is a simultaneous work with several products

being at different life-cycle stages: design, engineering, prototyping,

technology development, creation of pilot sample, pilot lot or even small lot

[1]. Besides, the simultaneous work is usually supplemented by the necessity of

the account of instrument-making products (IMPs) used in CAS-type systems which

form product lines with extending range and constantly improving components.

The mentioned feature of pilot

production points out to the necessity to coordinate the IMP and CAS life cycles

according to the ISO/IEC 12207 standard. This coordination should include

parallel spiral interconnecting of design and engineering solutions resulting

in the creation of IMPs.

It is easy to agree that under the mentioned

conditions the value of IMPs for CAS depends, to a substantial extent, on how useful

the combination of design and engineering solutions and actions will be for pilot

production of IMPs. It should be noticed that controlled and effective combination

of design and engineering constituents in production-engineering of pilot

instrument-making production represents a problem which has not been solved by

now.

The article proposes a set of tools

for representation and mixing of design and engineering actions whose creation

and use are based on aspect-oriented design of workflow systems using the

software suite TechWIQA created by the authors on basis of the question-and-answer

modeling environment WIQA [2]. A task tree and question-and-answer models created

in this environment, enable to model workflows in different versions of their operational

mixing. At that, reasonable solutions are searched for using libraries for

typical design and engineering works.

The development purpose is to implement the set

of tools ensuring intellectual actions of a group of production engineers, into

design process [3]. The set ensures question-and-answer access to experience,

including its creation, modeling, systematization, transformation, storage,

accumulation and use.

A

methodology of object-oriented analysis and design was used during the work. As

a result, an engineering version of the methodology, based on a special kind of

reasoning (question-and-answer one) in a group of production engineers at the

stage of engineering-document design, was developed. Such system of tools is

for constructive service of reasoning of production-engineer group for a

certain project. The production-engineering control is one of the constituents

of the service.

A

set of works for design and engineering preproduction should

represent a coherent set of design and engineering business-processes, at that

each of them has a specified functional purpose and place in the set. However the

real practice shows that preproduction organization is not coordinated with

this requirement. The existing preproduction order is built not taking into

account reasonable design and engineering interconnections and particular

organizational and technical conditions for a specified type of production.

The problem is that, when making operational

engineering decisions and specifying engineering actions, it is necessary to take

into account not only cost estimating of design solutions but also other

values, and in the context of the specifications of the CAS under development.

The same is right for operational design solutions and actions.

The design and engineering constituents

of the common work should contribute to a common agreed solution. It is reasonable

to consider the combination of sets of design and engineering works from the point

of view of workflows [4] which are effectively mixed. It should be noticed that

workflow (in its most general meaning) is understood as a computer-aided business-processes

(full or partial, as a rule, within an

organizational structure describing functional roles and relations)

where documents, information, tasks are transferred in order to perform required

actions, from one participant to another according to a set of procedure rules.

Let's proceed

to details concerning the interconnections of the preproduction design and engineering

constituents. Traditional methods of preproduction design and engineering do not

enable to co-ordinate such very important links of preproduction as support of

adaptability to manufacture of product designs, design and engineering analysis

of product, development of labor standards, objective operational and

production, technical and economic planning, definition of a range of required techniques.

The tasks of

engineering-process design are

multi-variant. They include selection of equipment, cutting tools, techniques, calculation

of cutting methods etc. The engineering process under development has a considerable number of possible combinations of

transitions, charts, processing methods and operation combinations even for

simple parts.

Different

variants of manufacture processes of the same products in consequence of the structure

differences have different outputs: performance, prime cost, metal consumption,

equipment utilization etc. The availability of several variants for task solution

(engineering-process variants) results evidently in the task of the selection

of the best variant. In this case the best one is an engineering-process variant

ensuring the fulfillment of all the design-document requirements under

particular production conditions and returning the best output values. At that,

it should be noticed that the present-day stage of engineering-process development

automation is featured by the creation of complex systems including design, process

engineering and manufacturing of instrument-making products.

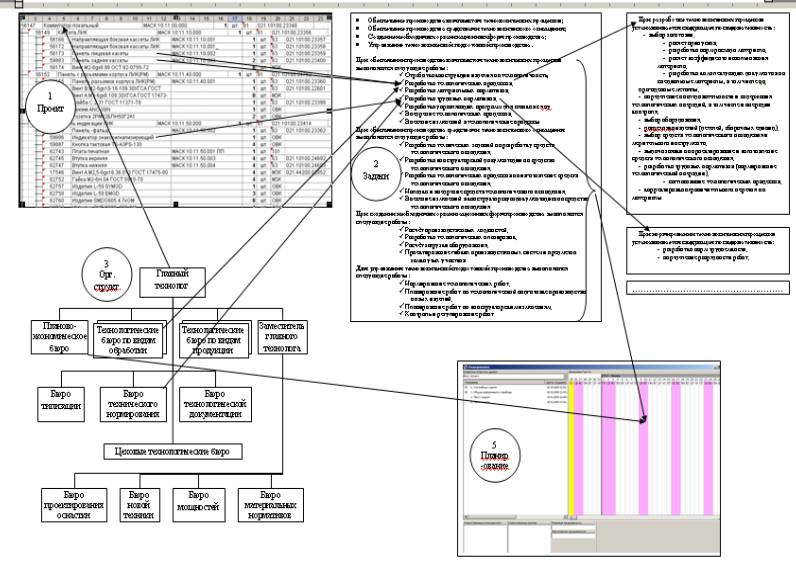

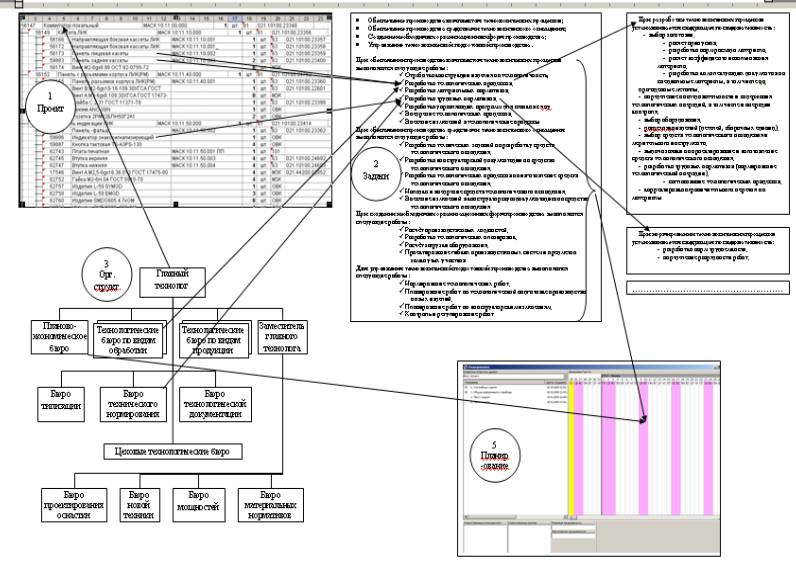

A generalized scheme of design

and engineering preproduction is shown in Figure 1 to demonstrate tasks to be

solved jointly within a specified organizational structure using standard and

reference data.

An engineering process as a

design object can be represented in form of a hierarchical structure divided into

several interconnected levels. As a result of such decomposition the process of

engineering-process design is reduced to the solution of tasks of different

levels of detail at the interconnected levels: from creation of composition and

structure of manufacturing route to development of control programs and

calculation of cutting modes to process some surfaces.

According to

the authors’ strong opinion, in automation of design and engineering

preproduction processes, thus in development of software for support of design

and engineering preproduction, it is reasonable to connect creation and solution

of a system of hierarchical tasks, and workflows of design and engineering

preproduction.

For

the computer-aided support of design and engineering preproduction processes on

basis of experience in workflow control, the authors developed a specialized

version of question-and-answer modeling environment for the development and

control of production engineering processes. The potential of the environment

is sufficient to support both engineering and design workflows. However from

the point of view of the content of support facilities the design part is

considered only from the positions of mixing of design and engineering tasks.

It should be noticed again that the

version proposed by the authors, enables the support of the development of single

engineering processes, repair of products and their components.

As a base, we used and adapted

a question-and-answer environment of CAS conceptual design NetWIQA. The result

of the adaptation, named TechWIQA, consists of the following components:

I. back end: 1. infobase;

2. library to work with

database;

3. application server;

4. client library;

II. front end:

1. configurator;

2. user’s WS;

3. plug-in to control staff

organizational structure;

4. plug-in to plan on basis of

Gantt charts.

Figure 1: Workflows for

Control of Production Engineering

The two components of the

system front-end were additionally developed:

1)

a plug-in to

control product structure, which ensures user interface to entry and edit hierarchy

of structure elements of a product under development, as well as support of required

references corresponding to different classifiers used in development of engineering

processes;

2)

a plug-in to

develop engineering processes, which ensures user interface to entry and edit

engineering-process operations, data of engineering norm-fixing, as well as the

creation of document sets for single engineering processes.

During the adaption, in the infobase structure 14

tables were left. They are required for storage of main data of the

question-answering environment, sufficient to solve given tasks. The tables are

following: projects (Projects), question-and-answer protocol (QAReg), types of QA-protocol

units (QATypes), status of QA-protocol units (QAStatus), reasons for status of QA-protocol

units (Reason), staff list (ManningTable), workers who are users of the question-and-answer

environment (Users), working groups (Groups), user joining working groups (GU),

tree of organizational structure (TreeNode), functional links of elements of

organizational structure (FuncLinks), task assignment to users (UT), task

assignment to working groups (GT),

planned terms for task fullfilment (PlanDates).

According to this, only

functions required for the work with data of the above tables were left in

other back ends.

We decided to use the question-and-answer

protocol for storage of reference data, product structure, engineering

processes and documents on them. In comparison with the addition of special

working tables for such data, this decision enabled to reduce the time for the

development of the system back-end, and the most important thing is that it

enabled to use mechanisms of data entry and editing, search and filtration,

access control, support of update history implemented for the question-and-answer

protocol. Besides, the decision enables to extend easily attributes of used

data, to implement developed components into workstations with different installed

versions of the question-and-answer environment due to the fact that the back-end

components are not required to be changed and the data transfer is not required

to be simplified.

The use of the question-and-answer

protocol for data storage assumes a computer-aided addition of task hierarchies

into it, questions and answers on basis of question-and-answer templates. We

included the following six files of these templates into the back-end in the

current version of the system:

1.

question-and-answer

templates for directories (file Directory.ini), containing the directory names

and types (hierarchical or list), as well as questions to display the directory

attributes. If the use of new directories is required, this file can be easily

added. That enables to increase the number of used classifiers without programmers’

help;

2.

a

question-and-answer template for product structure (file Structure.ini),

including questions to display attributes of product elements and lists of

possible values of some attributes. The hierarchy of the product-structure

elements is based on the hierarchy of QA-protocol tasks;

3.

a template

of tasks to be solved while creating and controlling engineering processes

(Tasks.ini file), including, e.g., ‘Generation of Documents on an Engineering

Process’, ‘Norm-Fixing for Engineering-Process Operations’ etc., as well as list

of required documents;

4.

a question-and-answer

template for structure of engineering process (file TechProc.ini), including

questions to display the attributes of engineering-process operations, used

equipment and man-hours in these operations, availability of parts, assembly

units and materials used for engineering process;

5.

a question-and-answer

template for methods sheet (MK.ini), including questions answers to which are

required to generate method sheets by all the types of forms according to a

selected type of engineering-process description;

6.

a question-and-answer

template for engineering instruction (TI1.ini), including standard content of engineering

instruction, e.g., on thermal processing of polymers, as well as questions answers

to which are required to generate such instructions for a particular engineering

process.

We included functionalities

for the work with data of the above templates into the application server and

client library. In the final version of the system, the template set will be extended

due to the inclusion of question-and-answer templates of all other kinds of

documents created during the development of single engineering processes according

to the GOST 3.1119-83 standard [5].

During the update of the

plug-in for the control of the staff organizational-structure a function to set

plan terms of the beginning and end of works and assign tasks to users and

working groups was implemented.

The

specific character of functionality and use principles of the additionally

developed component will be presented by fragments using basic interface

solutions of the TechWIQA tools.

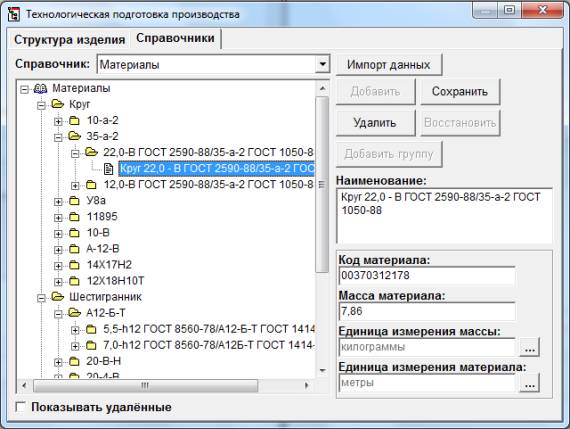

Figure 2 shows a form of the

component ‘Control of Product Structure» for the work with data of classifiers

used during the work with engineering processes. In the given window you can browse

the directory content, work with its elements (element group), set values for

attributes, as well as import the content from other projects using similar classifiers.

Figure 2: Interface for Work with Directories

Figure 3 shows an

interface to control product structures, implying the entry of product-structure

elements taking into account their hierarchy, setting of their attribute

values, registration of tasks for the work with engineering processes for elements

being manufactured, selection of a description type of engineering processes as

well as setting of list of documents on them.

Figure 3: Interface for Control of

Product Structure

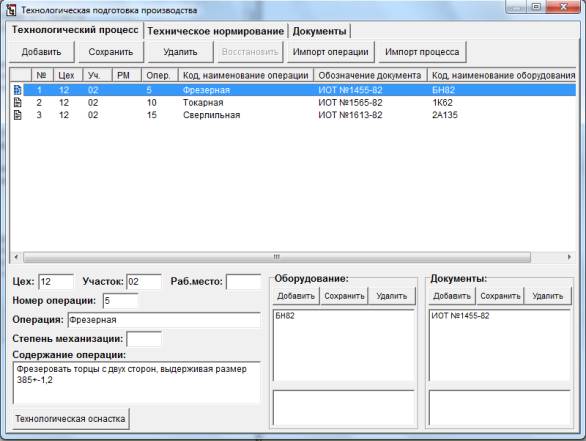

Figure 4 shows an interface

for the component «Engineering Processes» regarding the work with operations of

engineering processes under development. While working with the given

component, the employees responsible for the development of engineering

processes, add or edit their operations, specifying the key parameters:

designations of a shop, section and workstation where an operation is performed,

operation number and name, mechanization degree, lists of used equipment and

documents.

The operation content and

lists of used tools and jigs (production accessories) are also indicated within

a selected route description of an engineering process. The data on the product

completing with parts, assembly units or materials are also specified within a

selected route and operation or operation description.

For convenience, there is a

function to import engineering processes and their separate operations from

other structural elements of products or other projects.

In the window ‘Technical Norm-Fixing», the

employees responsible for this part of the work, enter pre-calculated data of parameters

for technical norms for each of the registered operations.

The window ‘Documents’ ensures

an interface to form a set of documents on an engineering process under a preliminary

selected list. First, the new documents are generated by templates or imported

from other engineering processes, then the data are downloaded from the server,

the document parameters are filled in and saved. After that, the documents can

be generated according to GOST standards in the Microsoft Word format, at that the

data of engineering-process operations and technical norm-fixing are borrowed

and do not demand re-entry.

Figure 4: Interface to Set

Operations of Engineering Processes

The current version of the system

ensures the support of the generation of methods sheets for engineering

processes for all the kinds of description as per the GOST 3.1118-82 standard [6] as well as engineering instructions as per the GOST 3.1105-84 standard [7].

The computer-aided

system of question-and-answer conceptual design of engineering documents and control

of production-engineering processes during manufacture of instrument-making

products increases considerably the efficiency of production-engineering

management at an enterprise due to the following:

¾

acceleration

of technological projects and, therefore, the whole production process;

¾

efficient

use of labor and information resources for engineering works in design production;

¾

improvement

of quality of engineering solutions in whole for instrument-making production;

¾

reduction of

costs for development of engineering documents (methods sheets, part lists).

REFERENCES

1. Норенков А.П.,

Маничев В.Б. Основы теории и проектирования САПР. М.: Высшая школа, 1990.

2. Соснин П. И. Концептуальное моделирование

компьютеризованных систем: учеб. пособие. Ульяновск: УлГТУ, 2008.

3. Соснин П. И.

Вопросно-ответное моделирование в разработке автоматизированных систем.

Ульяновск: УлГТУ, 2007.

4. Основы ИПИ-технологий: учеб. пособие / под общ. ред А.Н.

Тихонова, Ю.В. Полянского. Ульяновск: УлГТУ, 2006.

5. ГОСТ 3.1119-83. ЕСТД. Общие требования к комплектности и

оформлению комплектов документов на единичные технологические процессы. М.:

Издательство стандартов, 1985.

6. ГОСТ 3.1118-82. ЕСТД. Формы и правила оформления

маршрутных карт. М.: Издательство

стандартов, 1987.

7. ГОСТ 3.1105-84. ЕСТД. Формы и правила оформления

документов общего назначения. М.: Издательство стандартов, 1992.