Yerubay A.A., Bishimbayev V.K., Shevko

V.M.

Ph.D

student, Dr of Technical Sciences.

M.Auezov South-Kazakhstan

State University

Shymkent, Kazakhstan

Thermodynamic

modeling of interaction of calcium sulfate with carbon oxide (II)

For processing large-tonnage

production wastes of extraction phosphoric acid that is phosphogypsum some

variants of producing phospholime from it have been offered.[1-3] It is shown

by semi-industrial tests, that the degree of phosphogypsum decomposition in

rotating tube furnaces and fluidized-bed furnaces comprises 94- 97%. Formed by

this phospholime contains 58-76% of ÑàÎ. Process of

phospholime production from phosphogypsum now is not yet fully perfect, as the

content of CaS and CaSO4 in the product comprises accordingly 0,6-1,4

and 0,8-4,9%.

The task of the present work

was to determine optimum parameters of CaSO4 decomposition in

presence of CO as applied to agglomeration processing of phosphogypsum,

providing incomplete oxidation of natural coal carbon.

Research was carried out by

the method of thermodynamic modeling and a method of mathematical planning with

further optimization of technological parameters on the computer. For

thermodynamic modeling the program complex “Astra” developed in N.E. Bauman Moscow

High Technical School was used. Fundamental principle of a maximum entropy is

put in the basis of algorithm.[4,5] This method gives a unique opportunity of

the generalized description of any high-temperature state with the help of

thermodynamics fundamental laws, irrespective of conditions and ways of

achieving equilibrium. The database of the program complex Astra contains

information on thermodynamic properties of 5547 individual substances

systematized in Institute of high temperatures of the Russian Academy of

Sciences and the USA National bureau of standards.[6,7] The information

received by means of the program complex “Astra” allows to determine the

equilibrium degree of initial system elements transition into products of

reaction, and also composition of gas and condensed phases. Influence of

temperature (Ò from 500 to 1800Ê)

was investigated and distinct from [8,9] influence of a number of moles in

system CaSO4 – nCO (n from 0,2 up to 2,5) on the equilibrium

degree of Ñà distribution, including its

distribution in ÑàÎ was studied.

The carried out research has

shown, that the interaction happens with participation of 22 substances: CaSO4,

CaCO3, CaO, CaS, CO, CO2, COS, CS2, S, S2,

S3, S4, S5, S6, S7, S8,

SO2, SO3, SO, S2O, O2, O in system

CaSO4 – nCO depending on

temperature and number of CO moles. In figure 1 the information about influence

of temperature and number of CO moles on the degree of (α) calcium

distribution is given from which it follows that the basic calcium containing

compounds in the system are CaSO4, CaCO3, CaS and CaO.

From (Figure 1) it follows that in examined systems irrespective of CO moles number

in a temperature interval 500 – 600K

CaCO3 is being formed. The degree of formation (for example at Ò = 500Ê) CaCO3 grows with increase

of CO moles number in the following sequence:

|

n |

0,2 |

0,45 |

1,0 |

1,55 |

1,8 |

2,5 |

3,0 |

|

αCaCO3,

% |

6,62 |

14,88 |

33,30 |

51,43 |

58,44 |

89,97 |

98,82 |

Thus dependence ![]() looks like:

looks like:

![]() (1)

(1)

for which the criterion of suitability of approach R2 (factor of determination) comprises 0,9997.

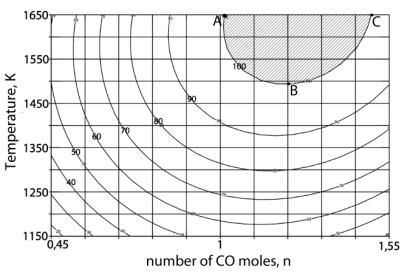

Figure. 1. Influence of

temperature and CO moles number (n)

in system CaSO4 – nCO on

the degree of calcium distribution (α) at pressure 0,1MPa. Where: 1 – CaCO3;

2 – CaSO4; 3 – CaO; 4 – CaS. In figures a), b), c), d), e), f), g) CO moles number (n) varies as

follows: à) – n=2,5; b) – n=1,8; c) –

n=1,55; d) – n=1,0; e) – n=0,45; f) – n=0,2

CaS starts to be formed in

systems at Ò ≥ 600K. Moreover, with

the increase of CO moles number the degree of CaS formation and temperature

area of its existence grow. So αmaxCaS

grows as follows:

|

n |

0,2 |

0,45 |

1,0 |

1,55 |

1,8 |

2,5 |

3,0 |

|

αmaxCaS, % |

4,99 |

11,18 |

24,80 |

38,56 |

44,7 |

63,19 |

73,6 |

Dependence ![]() looks like:

looks like:

![]()

![]() . (2)

. (2)

ÑàÎ is formed in system at T > 1100K. The temperature of CaO formation start (ÒstartÑàÎ) depends on number

of CO moles in the system, changing (decreasing) as follows:

|

n |

0,2 |

0,45 |

1,0 |

1,55 |

1,8 |

2,5 |

3,0 |

|

ÒstartÑàÎ, K |

1237,3 |

1207,5 |

1166,2 |

1142,6 |

1136,5 |

1126,1 |

1116,3 |

Thus dependence ![]() looks like:

looks like:

![]()

![]() . (3)

. (3)

Figure. 2. Influence of

temperature and number of carbon oxide moles in the system CaSO4 – nCO on the degree of ÑàÎ formation (α)

at Ð=0,1ÌPa,where CO moles number (n) are specified at modeling

as follows 1-n=0,2; 2-n=0,45;

3-n=1,0; 4-n=1,55; 5-n=1,8; 6-n=2,5.

Appreciable formation of ÑàÎ in systems is being observed at T > 1300K. Moreover,

with the deviation of CO moles number from 1 it results in reduction of the

degree of ÑàÎ formation from CaSO4.

At n = 0,2 ÷ 0,45 the process is

being blocked and it does not get any development in a temperature interval

1400 – 1700K (Figure 2). At constant

temperature (for example 1600Ê),

close to technological temperature of agglomeration the influence of CO moles

number on αÑàÎ has an extreme

character:

|

n |

0,2 |

0,45 |

1,0 |

1,55 |

1,8 |

2,5 |

3,0 |

|

αCaO, % |

19,94 |

44,85 |

96,54 |

91,65 |

83,69 |

63,50 |

32,84 |

Influence CO on ÑàÎ is described by

the equation:

![]()

![]() . (4)

. (4)

The research was continued

employing rotortable plans of the second order to search optimum parameters of ÑàÎ production from CaSO4 in presence of CO.[10]

Temperature (Ò,Ê) and

number of CO moles (n) as applied to

reaction CaSO4+CO=CaO+CO2+SO2 were used as

independent factors. The degree of ÑàÎ (αÑàÎ, %) formation was the parameter of optimization. The

matrix of conducting the research and results of ÑàÎ formation, received by means of program complex Astra, are given in (Table

1) Using the program developed in SKSU (South-Kazakhstan State University) it

was defined, that the equations of regression αÑàÎ=f (T, nÑÎ) in the coded and natural scale have

accordingly the following types:

![]() (5)

(5)

![]()

![]() (6)

(6)

The received equation is

adequate, because the tabular value of Fisher’s criterion (6,59) is bigger than

the real value of this criterion (5,59).[11] On the basis of the received

equation of regression using the program complex MathCAD – 14 the volumetric picture

of the change of response surface (Figure 3) and its horizontal sections (Figure

4) was constructed.[11] As follows from (Figure 3), the surface of

the response has an extreme character. Moreover, the maximum of ÑàÎ formation should be expected in the technological

area limited by figure ABC (Figure 4), that is, at Ò from 1490 up to 1690K and n from 0,1 up to 1,49. The composition

of gas phase of the system in this case (at n = 1,1) depends on temperature (Table 2).

In technological area (1500 – 1700Ê)

the gas phase contains 49,79 – 49,84% ÑÎ2 and 49,87 – 49,88% SO2.

Table 1. Matrix of planning

research and results of the research of ÑàÎ production from

CaSO4 – nCO system at Ð = 0,1MPa

|

¹ No. |

Independent variables |

αCaO, % (researched). |

αCaO, % (calculated). |

|||

|

Coded type |

Natural type |

|||||

|

Õ1 |

Õ2 |

n |

Ò, K |

|||

|

1. |

-1 |

-1 |

0,45 |

1446 |

46,8 |

48,08 |

|

2. |

+1 |

-1 |

1,55 |

1446 |

84,6 |

85,95 |

|

3. |

-1 |

+1 |

0,45 |

1654 |

47,8 |

49,09 |

|

4. |

+1 |

+1 |

1,55 |

1654 |

96,0 |

97,36 |

|

5. |

+1,414 |

0 |

1,8 |

1700 |

78,0 |

76,63 |

|

6. |

-1,414 |

0 |

0,2 |

1400 |

17,2 |

15,72 |

|

7. |

0 |

+1,414 |

1,0 |

1700 |

99,8 |

98,46 |

|

8. |

0 |

-1,414 |

1,0 |

1400 |

91,3 |

89,68 |

|

9. |

0 |

0 |

1,0 |

1550 |

99,4 |

98,54 |

|

10. |

0 |

0 |

1,0 |

1550 |

99,0 |

98,54 |

|

11. |

0 |

0 |

1,0 |

1550 |

98,6 |

98,54 |

|

12. |

0 |

0 |

1,0 |

1550 |

98,7 |

98,54 |

|

13. |

0 |

0 |

1,0 |

1550 |

97,0 |

98,54 |

To define the reasons of the

low degree of ÑàÎ formation at small (0,5) and

high (2) CO moles number we also determined the distribution of S, O and C

except Ca. On the basis of this the equations of CaSO4 interaction

with various quantity of CO are given in (Tables 3 and 4).

Figure.

3. Influence of CO moles (n)

number and temperature (T) on the

form of the response surface - αÑàÎ, %

Figure. 4. Horizontal section

views of the response surface – αÑàÎ. Figures on lines –

αÑàÎ, %.

Table 2. Influence of

temperature on composition of the gas phase of CaSO4 – CO

system at Ð = 0,1MPa

|

Content of form. % |

Temperature, K |

||||||

|

1200 |

1300 |

1400 |

1500 |

1600 |

1700 |

1800 |

|

|

CO2 |

97,28 |

88,61 |

50,69 |

49,79 |

49,91 |

49,84 |

49,67 |

|

CO |

1,22 |

1,61 |

1,27 |

0,44 |

0,18 |

0,15 |

0,28 |

|

SO2 |

1,47 |

9,67 |

47,49 |

49,72 |

49,88 |

49,92 |

49,87 |

|

SO |

0,9*10-3 |

0,011 |

0,079 |

0,03 |

0,015 |

0,013 |

0,028 |

|

S2 |

0,008 |

0,069 |

0,42 |

0,8*10-3 |

- |

- |

- |

|

CaS |

0,012 |

0,021 |

0,022 |

0,2*10-3 |

- |

- |

- |

|

S |

- |

- |

0,8*10-4 |

0,2*10-4 |

- |

- |

- |

|

SO3 |

- |

- |

0,2*10-3 |

0,001 |

0,01 |

0,017 |

0,019 |

|

O2 |

- |

- |

- |

0,3*10-4 |

0,003 |

0,053 |

0,13 |

Table 3. The chemical

equations of interaction in system CaSO4 – 0,5CO

at Ð = 0,1MPa

|

Temperature, K |

Equations |

|

500 |

CaSO4+0,5CO

= |

|

700 |

Product

1 = |

|

1200 |

Product

2 = |

|

1400 |

Product

3 = |

|

1700 |

Product

4 = |

Table 4. The chemical

equations of interaction in system CaSO4 – 2CO

at Ð = 0,1MÐa

|

Temperature, Ê |

Equations |

|

500 |

CaSO4+2CO

= |

|

700 |

Product

1 = |

|

1200 |

Product

2 = |

|

1400 |

Product

3 = |

|

1700 |

Product

4 = |

It follows from comparison of

given (Tables 3 and 4), that not full CaO formation from system CaSO4

– nCO at surplus of CO is linked with

formation of irreducible CàS. When there is a lack of CO production CaO is

restrained by existence of CaSO4 in wide range.

If to lower pressure in the

zone of reaction it is possible to reduce ÒmaxÑàÎ in the system CaSO4 – CO. So, at Ð = 0,01ÌÐà ÒmaxÑàÎ = 1400K, at

Ð = 0,001MÐa –1300K. At presence of SiO2 in

phosphogypsum up to 17%, ÒmaxÑàÎ with formation of CaSiO3 at Ð = 0,001ÌÐa makes 1000K.

For phospholime this process is negative, as it reduces ÑàÎ activity. However for the subsequent production of

ferrumsilicocalcium from agglomerate, presence of SiO2 positively

influences CaSO4 decomposition.

On the basis of the carried

out research of interaction CaSO4 with CO it is possible to draw the

following conclusions:

- originally in system at Ò = 500K ÑàÎ is formed, and the

degree of its formation grows at increase of CO moles number;

- restoration of CaSO4

to ÑàÎ goes through a stage of CaS

formation;

- the degree of transition

CaSO4 to CaS grows at increase in CO system;

- ÒstartÑàÎ decreases from 1237,3K to 1116,3K at increasing the number of CO moles

from 0,2 to 3,0;

- ÒmaxÑàÎ (> 99,5%) at Ð = 0,1MÐa is being observed in a temperature interval

1500 - 1700K number of CO moles = 1,1

– 1,5;

- influence of temperature and

number of CO moles on αÑàÎ from CaSO4

has an extreme character;

- reduction of pressure from

0,1 to 0,001MÐa and input in

system SiO2 positively influence CaSO4 decomposition,

allow to reduce ÒmaxÑàÎ to 1000K.

References

1.

V.V. Ivanitskij, P.V. Klassen, A.L. Novikov Phosphogypsum and its use.

Moscow: Chemistry, 1990. 224 p.

2.

L.M. Razdorskih, S.V. Hrjashev, N.L. Solodjankina etc. Industrial tests

of process of thermochemical decomposition phosphogypsum on calcium oxide and

sulphurous gas in the furnace of a boiling layer. II Works of SRIFI (Scientific

institute of fertilizers and insect fungicides) «Use of phosphogypsum in a

national economy». Moscow 1983. Issue 243. p. 57-67.

3.

Technology of phosphoric and complex fertilizers / Under edition of S.D.

Evenchika and A.A. Brodskogo. Moscow: Chemistry 1987. 464 p.

4.

G.B. Sinjarev, N.A. Vatolin etc. Application of the COMPUTER for

thermodynamic calculations of metallurgical processes. Moscow: Nauka, 1982. 263

p.

5. B.G. Trusov, S.A.

Barak etc. the Automated system of the thermodynamic data and calculations of

equilibrium conditions // Mathematical methods of chemical thermodynamics.

Novosibirsk 1982. p. 213-219.

6.

JANAF Thermochemical tables, 2nd edition. NSROS-NBS US Gov

Printing Office, Washington, DC, 1971. 1141 p.

7.

Thermodynamic properties of individual substances. A reference book by

media in L.V. Gurvich, I.V. Vejtsa others in 4 volumes. Moscow: Nauka, 1982.

559 p.

8.

V.M. Shevko, E.YA. Kalashnikov, V.A. Êàpsaljamov

Opportunity reception ÑàÎ at interaction

ÑàSÎ4 with Í2, C, CO, ÑÍ4 // Works of the international

scientific – practical conference «Àuezov readings – 4»

and the third scientific conference of high schools of Southern region.

Shymkent 2004. p. 99-103.

9.

E.YA. Kalashnikov. Development of technology of reception calcium

carbide from phosphogypsum. A dissertation of

Candidate of technical sciences, Shymkent, 172 p. 2010.

10. S.A. Ahnazarov,

B.V. Kafarov Method of optimization of experiment with the chemical industry.

Moscow: the higher School, 1978. 319 p.

11. V.F.Ochkov. Mathcad

14 for students and engineers. St.-Petersburg.: BHV-Petersburg, 2007. 368 p.