Математика/5. Математическое

моделирование

G.G. Shvachych, М.А. Sobolenko

National metallurgical

academy of Ukraine,Dnepropetrovsk, Ukraine

MATHEMATICAL DESIGN OF MUCH

SEQUENCING MODE OF HEAT TREATMENT OF LONG GOOD

Introduction. Presently, for preparation metal to cold deformation

spheroidizing and recrystallization annealing are used. This is conducted to

achieve the purpose of increasing plasticity of the metal and removal of

peening [1]. Heat treatment of metal is carried out in the stoves of mine type

or bell-shafted stoves in a protective atmosphere. The deficiency of these

traditional methods of preparation metal to cold deformation is heavy the

considerable expenses of electric power and gas at annealing of metal in

furnace, their low productivity, complication of providing the even heating and

cooling of hanks of wire.

As the alternative for

the indicated process of the furnace heating with electro-heat treatment is the

method of heat treatment, the distinetive characteristics of which are high

speeds of heating. In settings of the electro- contact heating treatment of

metal is executed continuous-consistently, that allows to mechanize and

automatize processes, quickly to pass to the new modes of heat treatment. For

the terms of wiffetss production (production of wire) this circumstance is

determining at creation of new technological processes [2].Complication of

development of technological lines consists in the much cyclic technological

process of treatment of metal (preparation of surface is cold deformation -

heat treatment) from a purveyance to the receipt of the required size of wire.

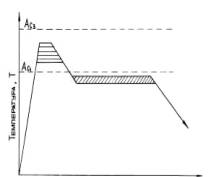

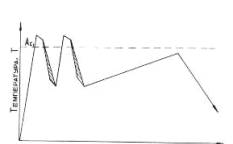

For example, heat treatment in a technological process can be carried out on

different charts (fig. 1 a, b) which depend on a brand became the set complex

of properties.

Planning of such line

requires implementation of difficult calculations and verification them in the

experimental-industrial mode at the choice of construction of setting and

descriptions of equipment, allowing to carry out the speed heating, following

after him isothermal self-control with the subsequent speed cooling.

time, s time, s

а) b)

Fig.1. Harts of the

spheroidizing annealing of wire with partial phase recrystallization and

subsequent isothermal self-control (a) and mulch cyclic mode of heat treatment (b)

Development and use of mathematical model,

characterizes the temperature field of metal in the process of heating,

self-control and cooling will allow to get information which can be used for

creation of equipment for the speed heating and cooling of long good.

Development of mathematical

model. The

interconnection of the thermal field with electromagnetic is conditioned that

the sources of heat are determined from the decision of electromagnetic task.

At the same time conductivity, dielectric and magnetic permeability of bodies

depend on a temperature. These dependences can have both smooth and saltatory

character. Character of these dependences influences at choice method of

calculation. It is very important, that all affecting of the electromagnetic

field properties of bodies and, in final analysis, on the coefficients of

equalizations show up through the changes of temperature and are inertia.

High-quality it is expressed in that thermal permanent time of the system and

its parts much more electromagnetic permanent. Therefore thermal and

electromagnetic tasks can be decided on certain temporal intervals independent

of each other with the step correction of associate sizes. A division is

conditional, because from the assumptions accepted at a calculation or from

calculation features all methods are given by results with a certain error.

Thermal processes are

described by Fure’s differential equalization that looks like [3]

![]() (1)

(1)

where w – is

volume closeness of internal sources of heat closeness of the material; ![]() - coefficients of heat capacity and heat

conductivity accordingly.

- coefficients of heat capacity and heat

conductivity accordingly.

If a transversal section

of wire is small as compared to long, and coefficient of heat conductivity ![]() is considerable, in equalization (1) it is

possible to put gradients of temperature on Y and Z equal to the zero. In this

case a task reduses to mono measuring, when the overfall of temperature takes

place only in the direction of longitudinal co-ordinate X. At such approach it

is possible to take into account heat emission in the most differential

equalization as a subzero source, and the interconnection of the thermal field

with electromagnetic will be conditioned positive sources heats which are

determined from the decision of electromagnetic task. Thus, the following

differential equalization of heat conductivity is simplified :

is considerable, in equalization (1) it is

possible to put gradients of temperature on Y and Z equal to the zero. In this

case a task reduses to mono measuring, when the overfall of temperature takes

place only in the direction of longitudinal co-ordinate X. At such approach it

is possible to take into account heat emission in the most differential

equalization as a subzero source, and the interconnection of the thermal field

with electromagnetic will be conditioned positive sources heats which are

determined from the decision of electromagnetic task. Thus, the following

differential equalization of heat conductivity is simplified :

![]() (2)

(2)

where W – is

amount of heat, conditioned converting of electromagnetic energy into thermal,

or given unit of volume of bar in time unit in an environment in the mode of

cooling. Thus, at the much cyclic mode a mathematical model (2) can describe

the modes, allowing to carry out both warming self-control and cooling modes.

For each of them the functional filling of source will be by it. In first case

the function of W corresponds the selection of heat which can be appraised by

Joule law. In the second case he can be presented as

![]() (3)

(3)

where ![]() - is a coefficient of heat exchange,

- is a coefficient of heat exchange, ![]() - relation of area of section of bar toward

the perimeter of section (

- relation of area of section of bar toward

the perimeter of section (![]() - for a

cylindrical bar, with radius R)

- for a

cylindrical bar, with radius R)

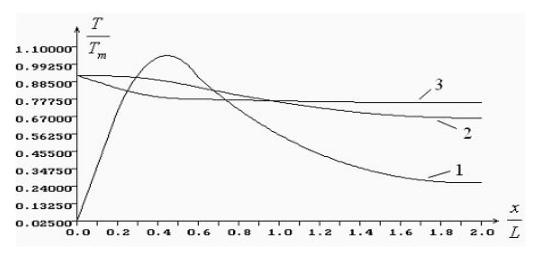

As in the much cyclic

mode of heat treatment, presented on fig.2, added every cycle except for the

sources, also moments of time and

amplitude of temperatures, there is possibility of problem (2) definition, (3)

as reverse. Under the structure of thermal model will understand a differential

model (2), (3). The specific features of thermal model are such, that for all

modes, reverse task, is the basic mean of receipt of necessary information at

the decision of tasks of thermal design for the chart of production line.

In this work Reverse

Task of Heat Conductivity decides by bringing it over to the extreme raising.

In-use approach consists of that at the decision of RTHC the sought after

causal descriptions of heat-exchange process are examined as parameters

managements, included in the decisions of direct tasks [4].

The presented raising of

task allows to decide a mathematical

model (2) within the framework of one of perspective in a decision

reverse tasks of heat exchange, proper their extreme raising with the use of

the known numeral methods of theory of optimization.

The results of decision

of reverse task on the developed approach are presented on a picture 2.

Conclusions

New approach is

considered to the problem of the speed heating and cooling of long good in the

technological stream of production of wire. The basic parameters of management

the speed mode of heat treatment are got on the basis of decision of reverse

task of heat conductivity, in which description of process examined as

management parameters. The mathematical design of speed process of heating and

cooling of long good showing efficiency offered approach.

Fig. 2. Much sequencing mode, including the rapid

heating(1), self-control(2) and cooling(3)

Reference

1. Долженков

И.Е., Долженков И.И. Сфероидизация карбидов в стали.-М.: Металлургия, 1984.-

143 с.

2. Колпак

В.П., Лещенко А.Н., Полторацкий Л.М. Комплексные линии электротермической

обработки стального проката и проволоки// Сборник докладов 4-ой Международной

конференции “Оборудование и технологии ТОМ и сплавов”.- Харьков.- 2003.-

С.42-44.

3. Немков

В.С., Полеводов Б.С. Математическое моделирование на ЭВМ устройств

высокочастотного нагрева. – Л.: Машиностроение, 1980. - 64 с.

4. Швачич

Г.Г., Шмукин А.А., Протопопов Д.В. Некоторые особенности математического

моделирования обратных задач исследования теплофизических свойств материалов//

Металлургическая теплотехника. Сб. науч. трудов НМетАУ в 2-х книгах. Книга

первая. – Днепропетровск: Пороги, 2005.- С.449-456.