Prof. S. Shestakov1, prof. O. Krasulya1,

prof. E. Smeshek2

1 Moscow State University of Technology and

Management, Russia

2 Polessky State University, Belarus

Sonochemistry of food - area

high-energy chemistry which actively is researched now in Russia and Belarus

Sonochemistry as a field of science is relate to the

subject of physical chemistry and is a part of high-energy chemistry.

Sonochemical method allows to have a direct impact on the reagents in

endothermic liquid-phase reactions and do not require heating of the solution

containing these reagents. The main factor of sonochemical reactions is the

giant pulses of fluid pressure from pulsating of cavitation bubbles - acoustic

cavitation. Bubbles in the compression phase is reduced in diameter to nanometer

dimensions, the gas-vapor mixture inside them are heated and turns into a

plasma, what is accompanied by the emission of photons - the sonoluminescence.

These rays can reach the energy of ultraviolet radiation. There are even

attempts to produce in cavitation bubbles filled with pairs of deuterated

acetone, a inertial thermonuclear fusion [1].

Reactions of hydration , in contrast to the hydrolysis

reactions is not accompanied by the dissociations of the molecules, but the

modern chemistry of tends to attribute

them to the chemical reactions, because, having polarity molecules the water

itself causes dissociation into ions of dissolved substances. Using this

approach, which limiting the food sonochemistry by reactions aimed at the

dipole-dipole and ion-dipole interactions in aqueous solutions, in Russia and

Belarus in recent years studies are in this area. Developed unique research

methods of sonochemical processes and devices, as well as technologies for food

and drug sonochemistry and the sonochemical reactors for their implementation.

In 2010, was successfully completed the state sanitary-epidemiological

inspection and certification of cavitation reactors special series to implement

sonochemical technologies in the food industry.

Setting

sonochemical processing of solutions salt used in products from minced meat.

One of the world's

leading food sonochemistry scientists – Dr. M. Ashokkumar, Professor,

University of Melbourne in 2011 visited his Russian colleagues-researchers. He

estimated the undertaken in Russia the approach to food sonochemistry, praised

of their research and myself took part in them [2,3].

Earlier sonochemical is thought only the

processes that occur in the gas phase inside the cavitation bubbles [4]. One of

the reactions of water, which not accompanied the dissociation of water

molecules – the destruction by pulses pressure from the ripple bubbles by

molecular structure of water which is formed by hydrogen bonds. The presence of

this structure, reminiscent of the structure of ice, even at room temperature

was once again confirmed by studies at Leiden University [5] and is associated to the polarity of the water

molecules. Reaction which break this structure by mass reagent (water) immeasurably

superior of reactions the pyrolysis in vapor phase of bubbles.

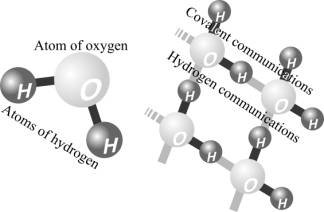

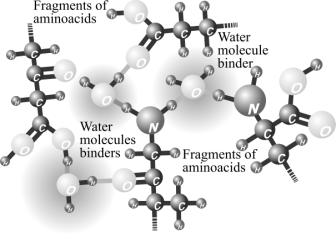

The water molecule and molecular structure of water

which is formed by hydrogen bonds.

As a result sonochemical reaction dehydration,

the water for a while loses structure and becomes thermodynamically

nonequilibrium state. In the Institute of Chemical Physics of Russian Academy

of Sciences by measuring proton magnetic relaxation in distilled water which

was subjected to sonochemical processing in the cavitation reactor, was

established how long this water returned to equilibrium. There established the

presence in the water after the treatment phases with different molecular

mobility, the separate existence of which there is approximately 2-3 hours.

During this period, energy of cavitation the

received by water is transformed into heat of hydration of water molecules

themselves, that is, into heat from recovery of hydrogen bonds in an amount

corresponding to the thermodynamic equilibrium.

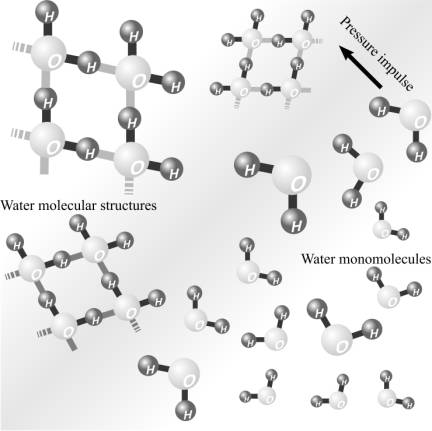

Scheme of destroying the molecular structure of water by cavitation.

The strong increase in the

viscosity of water as the temperature decreases, a paradoxical decrease in

density when cooled below +4°C, and high in comparison with non-polar

liquids, the surface tension is explained with phenomenon the self-hydration.

Unrelated molecules of water may to hydrate of biomacromolecules, creating

dense hydration shells around them. Hydration is the process of binding water

chemicals - chemical reaction, which produces a new substance. Chemistry of

biopolymers known that, for example, a protein with a molecular structure of

amino acids which have carboxyl –COOH, hydroxyl –OH and amine –NH2

polar groups, is capable as a result of hydration attach up to 40% water by

weight. [6] According to the teachings of Acad. V. Vernadsky, the water which

is connected in hydration is an integral part of the protein. It naturally

increases mass of protein, because actions the mechanisms similar to those that

occur during its synthesis and almost equally well how strong peptide bonds.

Food raw materials in today for the most part kept in the dried or frozen, that

is, has the loss of natural moisture or losing a bond with her. Therefore,

finding the ability to manage the hydration of biopolymers solves a huge

problem - reducing the number or excludes from food, nonfood substances, which

are traditionally used to artificially increase the binding of water and in

this way their mass.

Hydration process management

has become one of the main directions of development of food and drug

sonochemistry in Russia [3]. Hydration capacity of water in relation to other

substances depends on content in water of unstructured phase. When a source of

energy of disintegration of the the hydrogen bonds is disappears, they again

begin to recover in the amount corresponding to the thermodynamic equilibrium,

returning the absorbed energy as heat self-hydrations. The hydrogen bonds

disintegration by impulse of pressure cavitation occurs as is shown in figure:

![]()

![]()

kJ, (1)

kJ, (1)

where:

m – the number of molecular water associates in the reaction; n –

the number of water molecules is forming a stable associates; NA –

Avogadro's number.

Since the heat of vaporization

of water is equal to 44 kJ/mol, then she may be to devoid of structure

by heating. But if the goal is to increase the degree of hydration of

biopolymers, which are themselves unstable to thermal denaturation, thermal

fracture mechanism of hydrogen bonds is not acceptable. There are many known

ways of destruction of the structure of water without her heating. These

include all methods of mechanical action, such as processing in a colloid mill

or in a disintegrator of rotary type, and sometimes transfer the energy using

the polarity of water molecules [7]. A researcher working with the water is

prepared by the last way for kneading dough on baking, found that thickness of

the hydration shells of protein molecules is reduced and formed a more flexible

structure of the protein. This supports the hypothesis of the structuring of

protein by means hydration [8]:

The structuring of protein by

means hydration

These techniques improve the

solvent power of water is doing by means changing her energy state at the

expense of energy transformation different nature, temporarily deducing it from

thermodynamic equilibrium. The advantage of sonochemical effect in is that the

original chemical composition of the water does not matter. On the contrary,

the water may contain dissolved in any amount or suspended solids and they will

not be lost in the process of disintegration, as in the case of membrane

cleaning and do not to form undesirable chemical compounds as at electrolysis.

The latter is particularly important because for foods the content of mineral

substances and the content of useful trace elements is controlled by dissolving

them in incoming water. The cavitation in water is accelerate dissolution, ions

of dissolved substances get the dense hydration shells, which reduces their

ability to participate in unwanted chemical reactions. This is another advantage of sonochemistry.

Known a method of processing

grain aqueous solution of propionic acid before placing it into storage [9] and

the method of wetting grain with water (his conditioning) at production from it

flour [10]. In these methods, the liquid is exposed to ultrasound. Acoustic

processing power is not set explicitly, but in the second case is required to

form hydroxyl ions and synthesis of hydrogen peroxide which is known to be

implemented in two ways:

OH + OH → H2O2

(2)

O + HOH → H2O2, (3)

where one of its part formed from of the synthesized hydroxyl ions, in

the other is involved dissolved in the water oxygen [11]. Therefore in [10] is

provided preliminary oxygen saturation of water by means forced aeration. The

remaining hydroxyl ions in the water further destroy the structure of the grain

due to the effect of ion cracking. A hydrogen peroxide has detrimental effect

on the microflora and decomposed by enzymes of grain. Decomposition has

explosive character, which also destroys the endosperm of kernels. But this

method of preparation of water for hydration food stuff which include fats is

not suitable, because they can oxidize, leading to a deterioration of taste and

reduce the shelf life of products prepared from hydrated that way biomass. In

Russia and Europe was patented a sonochemical method of hydration of proteins

meat by water which processed in cavitation reactor at the amplitude of the

sound pressure in the 2 ... 23 times higher than the hydrostatic pressure in

him [12]. This method is not widely adopted due to short shelf life of foods,

such as sausages made with its use, even though it saves raw materials [13].

In Russia created the method

sonochemical processing of brine [14] and sonochemical method of processing the

water and water solutions to hydration biomass [15]. In they hydrogen peroxide

is not synthesized in significant quantities, because the amplitude of the

ultrasonic reactor pressure does not exceed twice the value of the hydrostatic

pressure in the liquid. But the decrease of the pressure amplitude of

ultrasound which causes cavitation and whose square of which is proportional

the acoustic power of the process, has led to a drastic decrease of performance

of the sonochemical processing. From the general physics we know that necessary

for any action energy is equal to the product of the power of the impact on its

duration. Therefore, such methods in the production of, for example, meat

products have been used only in catering [13], where produced small quantities

of products.

But there is a way of hydration of biopolymers by sonochemical processed

water or solutions on its basis [16]. In it sonochemical processing carry out

in the cavitational reactor with an average amplitude of sound pressure of the

elastic wave exceeding hydrostatic pressure not less than in 5,5 times. In the

description of this method examples of its implementation are given. In the

first example at hydration of proteins of a gluten of grain of wheat is

received the increase in weight of a crude gluten and reduction of the general

microflora. It is known that the adipose component of the grain is in its

embryo, which prior to processing of grain into flour is separated from the

grains. Therefore, the method has shown here a positive result. In the second

example sonochemical treatment of an aqueous suspension of mustard seeds to

extract from it the substances used in the manufacture of mayonnaise,

microbiological purity of the suspension medium and the content of organic

acids in it increased. In the following example as a result of water processing

for preparation of a brine at production semi-finished products from chopped

meat the content of microflora in forcemeat decreased, fat – is increased. It

is known that the analysis of the content of fat in foodstuff and semi-finished

products is carried out methods of extraction by Soxhlet and Randall. Therefore

it is possible to assume that the paradoxical increase in the content of fat in

meat is connected with the increased extractability of products of its

oxidation which formed at hydration by processed water. The given examples of

implementation [16] confirm that oxidizers in water nevertheless are formed in

sufficient quantities for oxidation of fats in a hydrated biomass.

Problem of the last researches conducted

by us is search of a way of decrease in the content in the processing water,

including, which being the environment of solution or disperse system,

oxidizers like hydrogen peroxide without decrease in acoustic power of the

sonochemical processing, and without to reduction its productivity.

In [11] are given experimental data about

H2O2 exit depending on the spent energy at synthesis by

ultrasonic fluctuations. Is noted, what hydrogen peroxide exit strongly depends

on a chemical composition of water, in particular, from the content in it the

dissolved oxygen of air. Later was a published result of researches about an

exit the hydrogen peroxide in the two-factorial experiment [8]. By means of it

it is established that this exit is optimized by function of two variables.

Existence of a local maximum is explained with by heating of water from

internal friction, decrease in the contents in it of oxygen and thermal

decomposition at increase H2O2 in time of processing and

acoustic power high over optimum values. It is known also that coincidence of

collapse of cavitational bubbles practically any primary diameter in water from

the end of the period of an acoustic wave which causing cavitation is comes

with amplitude of pressure approximately equal to five hydrostatic pressure

[13]. It is a so-called mode of sinperiodic cavitation. At increase above this

value the potential energy responsible for the size of a cavitational erosion

and a sonoluminescence both in singlebuibble and in multibubblle cavitation

remains to constant, and the kinetic changes only. Thus, the mode of

sinperiodic cavitation is most energetically favorable. But, as it was shown

above, usage [16] in the food industry is hinder the education in hydrogen

peroxide water in significant quantities. If to consider that the exit of

hydrogen peroxide depends on the content in water of the dissolved oxygen of

air, there was a hypothesis that is possible to lower it, previously having

subjected water or water solution of deaeration.

In [17] is described the fact of an invariance of

permanganat oxidability of solutions of free organic acids, which is subjected

sonochemical processing with an amplitude of acoustic pressure no more than 2 atm.

Influence of processing on hydration ability of water was estimated there by

efficiency of dissolution of tableted NaCl. Therefore experimental check of

correctness of this hypothesis it was carried out as follows.

Expenses of energy necessary on sonochemical water

processing are established in [15]. At the room temperature they make about 2 kW×h/m3.

In reactor described in [17] is installed the magnetostriction converter with

an electric power of 630 W, its absolute productivity makes 0,16 m3/h.

Productivity of the reactor of the Oil Tech Production OY company

(Tallinn) in [18], used in experiments, with piezoelectric converters is equal

1,08 m3/h, that is amplitude of sound pressure here is

2,6 times more and is equal to amplitude of sinperiodic cavitation. Considering

it, prepared three identical samples of solution of 0,4 mg/l tannin

which strongly predisposed to oxidation by

hydrogen peroxide. The permanganat oxidability of solution measured by a

method of Kubel, made 5,2 mgO2/l. The first sample

considered control and within 3 min in experimental installation

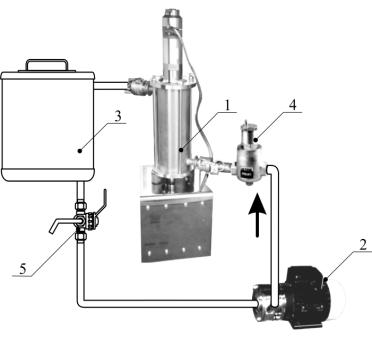

Experimental

installation with the cavitational reactor of the company Oil Tech

Production OY:

1

– reactor; 2 – pump; 3 – to a receiver;

4

– deaerator Caleffi 551; 5 – three-running crane.

recirculated it by

means of the pump via the reactor which was disconnected, receiver and turning

on deaerator after the pump. Method [16] was doing out on the second sample

with recirculating of solution within 1 min. The solution by means of the pump

passed via the switched-on sonochemical reactor, a receiver and at the

deaerator. Hypothesis checked on the third sample is processing it as follows:

within 2 min solution recirculated by means of the pump via the switched-off

sonochemical reactor, a receiver and deaerator, then for 1 min turned on the reactor. In all three cases

after the expiration of time of processing the pump disconnected, the crane to

solution plum and measured on ISO 8467 permanganate oxidability. In total five

series of experiences were doing. Results are shown in the table in the form of

average values with ranges of mean square deviations.

Table

|

parameter |

Unit |

value |

||

|

Sample 1 |

Sample 2 |

Sample 3 |

||

|

Permanganate oxidability |

mgÎ2/l |

5,12±0,05 |

2,31±0,07 |

5,09±0,05 |

From the table it is visible that permanganate

oxidability of samples 1 and 3 is almost identical whereas at a sample 2 it is

lower. It means that the part of tannin was oxidized by the hydrogen peroxide

which formed in the course of sonochemical processing. Further compared results

of dissolution of the tablets NaCl during identical time by immersion them in

the processed and non processed water. Results for sample 3 is similar to a

photo from [17]. It is visible that the difference of reduction of volume of

tablets dissolved in usual and to the sonochemical processed water is almost

identical. But in a sinperiodic mode it was required to time for sonochemical

processing much less.

|

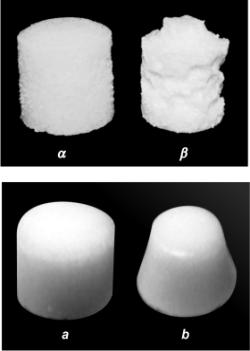

|

+

Tableted NaCl after

exposure to normal water a

(a) and water, which

subjected sonochemical processing b (b) in accordance with [17]

(top) and with [16], but with deaeration (bottom).

The

experiments have confirmed the validity of the hypothesis, as the yield of

hydrogen peroxide really depends on the content in the water of dissolved

oxygen. This allows you to use in the food sonochemistry most energetically

favorable mode the sinperiodic cavitation [13] subjecting the water or an

aqueous solution of forced deaeration. At the same time hydration and solvent

power of water can not fall off and time for sonochemical processing required

less than traditionally accepted in food sonochemistry. That is use in the food

industry the sonochemistry will be absolutely safe, if the take action which

prevent the formation of hydrogen peroxide in water way remove from the

solution the atmospheric oxygen.

References:

1. Taleyarkhan R. et al. Evidence for Nuclear Emissions

During Acoustic Cavitation. Science, V.295, 2002, 1868-1873

2. Ashokkumar M., Rink R.,

Shestakov S. Hydrodynamic cavitation – an alternative to ultrasonic food

processing. Electronic Journal “Technical Acoustics”, http://www.ejta.org,

2011, 9

3. Ashokkumar M. et al. A New Look at Cavitation

and the Applications of Its Liquid-Phase Effects in the Processing of Food and

Fuel. Applied Physics Research, Vol. 4, No. 1, 2012, 19-29

4. Margulis M. Basics

sonochemistry. Chemical reactions in the acoustic field. (Moscow: High School, 1984) (in Russian)

5. Jinesh K. B.,

Frenken J. W. M. Experimental evidence for ice formation at room temperature.

Physical Review Letters, 101, 2008, 036101.

6. Kuntz I.D. The physical properties of water

bound to biomacromolecules, in R.B. Duckworth (Ed.) Water relations of foods

(London: Academic Press, 1975)

7. Korchagin V.I. et al. Use in

baking temporarily activated

water. Baking in Russia, 5, 2000, 16-18 (in Russian)

8. Shestakov S.D. Basics of cavitational disintegration.

(Moscow: EVA press, 2001) (in Russian)

9. Patent RU 2122311,

1998

10. Patent RU 2171568, 2001

11. Flynn G. Physics of

acoustic cavitation in liquids,

in W. Mason (Ed.) Methods and devices

of ultrasonic researches (V.1, Part B, New York,

London: Academic Press, 1964)

12. Patent EP 1609368,

2007

13. Shestakov S. Food

sonochemistry: concept, theoretical aspects and practical applications

(Saarbrücken: LAMBERT Academic Publishing, 2012)

14. Patent RU 2402909,

2010

15. Patent RU 2444201,

2012

16. Patent application

WO/2007/111524, 2007

17. Krasulya Î.N., Shlenskaya T.V., Shestakov S.D. Experience using

sonotechnology in the food industry, Proc. XXII Session of Russian Acoustic

Society, Vol. 2, Moscow: GEOS, 2010, 68-74

18. Rink R., Shestakov

S., Babak V. The Sonochemical Reactors with Symmetric oscillatory Systems of

the Acoustic Cells International Journal of Research and Reviews in Applied

Sciences, Vol. 12, 3,

2012, 391-396