Edis Ten, Olga Sharaya

(Moscow Institute of Steel and Alloys, Russia

Karaganda State Technical University, KAZAKHSTAN)

Electronic and microscopic investigation of structure

and properties of sheet steel protection coatings

The

quality of surface of low-carbon construction sheet steel produced at

steelmaking plants requires perfection, as the volume of metal-made products

with protection coatings constantly increases.

The

main purpose of protection coatings is to protect products and structures from

corrosion. That is why steelmaking plants rapidly develop production of rolled

metal with anti-corrosion coatings (galvanization, chromium coatings,

enamelling, etc). The share of sheet steel products with coatings is now up to

40% in industrially developed countries. Such production is used in heavy

engineering, car-making, packaging and packaging materials manufacturing.

The

purpose of this work is to investigate the quality of low-carbon steel 08kp,

08ps and the structures of galvanized and aluminum-zinc coatings spread over

the surface 0.5… 0.22 mm thick.

It is known that the quality of metal products

with protection coatings is determined by the absence of surface deficiencies.

Thus, to develop technological solutions, the following tasks had to be

accomplished:

- the

formation of rolled metal surface deficiencies was analyzed and the development

of preventive measures ensured;

- the

zinc and aluminum-zinc coatings on strip steel 08kp, 08ps surfaces were

studied.

The

object of investigation was hot- and cold-rolled sheets of industrial rolled

metal as well as zinc and aluminum-zinc coated samples. The structure of metals

and coatings were studied by way of light microscopy (Carl Zeiss microscopes)

and with the dot-matrix electronic microscope JSM 5910 (made by JEOL).

Investigation results and their discussion

Sheet rolled metal surface deficiencies. Deficiencies are

classified depending on their character and nature and technological

redistribution on which they formed or appeared. There is complexity in identifying

the nature of deficiencies, as deficiencies of one type may be caused by

several factors (for example, steel-smelting or rolling redistribution). At the

same time, similarly manifested deficiencies may have a different nature. In

the course of further technological operations of steel reprocessing, the outer

appearance of deficiencies may change.

In most cases, thin-sheet strip steel

is used for stamping deep-drawing products, manufacturing tin and sheets with

anti-corrosion protection coatings, which virtually excludes any deficiencies

in the surface (base) layer.

We

have determined that main surface deficiencies in cold-rolled stripes and

sheets from low-carbon steels are scabs and rolled-out blowholes classified in

line with GOST 210014-88.

Deficiencies may be divided by default

into internal and surface ones, but in the process of production of end rolled

metal products internal deficiencies may appear/roll out on the stripe surface

and thus form surface deficiencies.

In the course of experiments, rolled

metal surface deficiencies were grouped into three types: low longitudinal

stripes with exfoliations; dark stripes in the form of parallel lines;

interrupted scaly exfoliations with transversal tears. Deficiencies in the form

of lines have basically appeared 100 mm from the edge of a roll and further

1/3-1/4 of the sheet's thickness deep.

By

using a micro-probe and the method of dot analysis and deficient area mapping,

we have managed to determine the structural and concentration heterogeneity:

non-metal phases of various types were recorded in deficient areas (they are

normally called non-metal inclusions). In 08kp steels, there were accumulations

of oxide non-metal inclusions of globular shape which had the following

composition (%): FeO - 91…93; MnO – 1,42…2,5; SiO2 – 0,16…0,98. Cavities

of blowholes (surface and subcutaneous) are partially or fully filled with

dross (ferrum oxides), allowing to carry out micro-probe analysis. Areas of

fragile-destroyed cindery ferrum-magnesium-silicate inclusions were also

observed. For 08kp and 10ps, the presence of raw non-metal inclusions in the

form of fragile-destroyed silicates was recorded in rolled metal, with the

following composition (%):SiO2 – 12…18; MnO – 30…58; FeO – 8…10. Ferrum oxides with 91.6% of FeO and 2.5 % of MnO were distributed between discontinuity flaws and

micro-pore cavities. In areas of strip rolled metal, where surface deficiencies

were not stated, there were no non-metal inclusions or ferrum oxides in the

form of dross.

Therefore, using micro-probe analysis

for researching micro-structures of steel has allowed to identify

characteristic types of rolled metal surface deficiencies and to classify them:

1 – scabs, 2 – rolled-out (oxidized) blowholes, 3 – raw non-metal inclusions

(deoxidization products, cinder). This permitted to figure out the causes of

deficiencies on the rolled metal surface and to work out recommendations for

their reduction, which contributed to obtaining more high quality coatings.

Investigation of zinc and

aluminum-zinc coating structures.

Rolled metal samples (150x150 mm) selected from strip

steel 08kp 0.5…0.22 mm thick and covered with zinc and aluminum-zinc coatings

were investigated with the dot-matrix electronic microscope. The coating's

thickness and chemical composition were measured. Picture 1 shows the structure

of a steel sheet with a protection coating.

• 1 • 2 • 3 • 4 • 5 • 6 10

![]() m

m![]()

Picture 1. –

Structure of a coated steel sheet

From the base of a sheet there are benchmark

points (1,2,3) drawn towards the edge (4,5,6) following which the distribution

of elements was investigated by analyzing energy spectrums of characteristic

X-ray radiation. The quantity X-ray analysis allowed to identify the

composition of phases inside the coatings and to recommend technological

parameters for zinc and aluminum-zinc coatings.

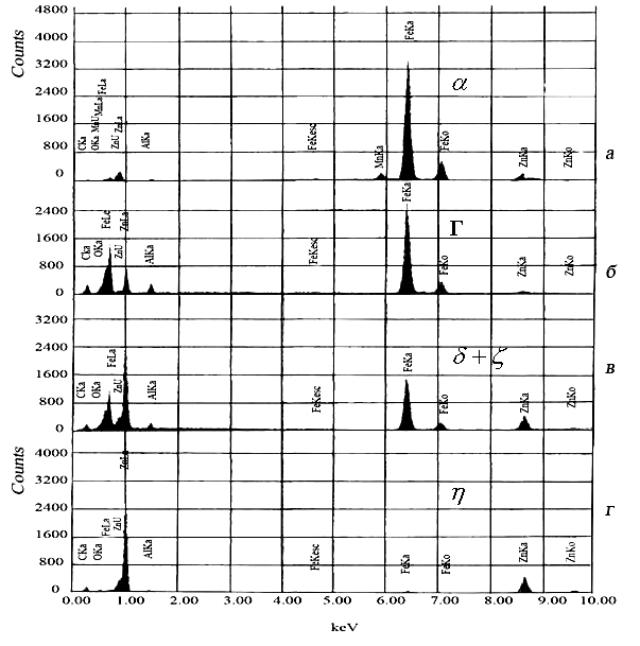

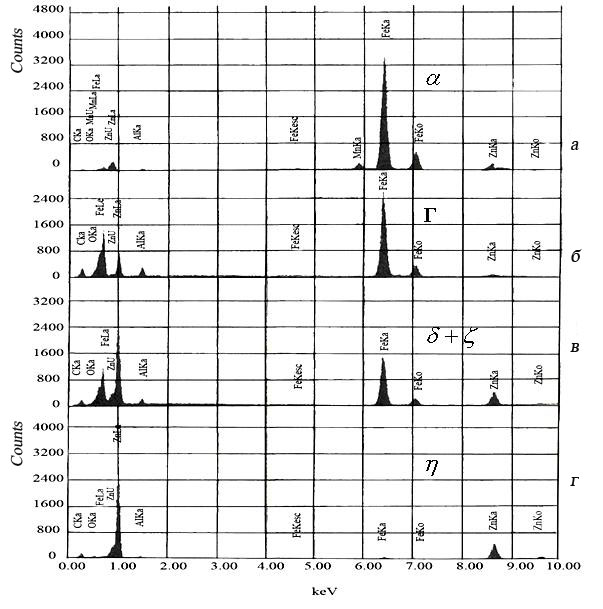

Picture 2 shows the characteristic spectrums of X-ray

radiation obtained from the relevant points (Picture 1). Point 2 corresponds to

an ![]() phase, whose energy spectrum (Picture 2,a) determines

the composition of the coating and contains 5.1% of zinc and up to 94.8% of

ferrum. The energy spectrum of radiation in point 3 (contains up to 79% of zinc

and up to 21% of ferrum) corresponds to a G phase (picture 2,b). In points 4

and 5, the decoding of spectrums (picture 2,c) allows to identify the chemical

composition of transition phases.

phase, whose energy spectrum (Picture 2,a) determines

the composition of the coating and contains 5.1% of zinc and up to 94.8% of

ferrum. The energy spectrum of radiation in point 3 (contains up to 79% of zinc

and up to 21% of ferrum) corresponds to a G phase (picture 2,b). In points 4

and 5, the decoding of spectrums (picture 2,c) allows to identify the chemical

composition of transition phases.

In accordance with the indicated points, one phase

contains up to 91.9% of zinc and up to 8.1% of ferrum and the other up to 93.8%

of zinc and up to 6.2% of ferrum. These concentrations of elements correspond

to ![]() phases. In point 6 (picture 2,d) only zinc was

identified at the level of 99.9%, corresponding to an

phases. In point 6 (picture 2,d) only zinc was

identified at the level of 99.9%, corresponding to an ![]() phase.

phase.

Experimental results of composition of intermediary

coating layers are given in Table 1.

Table 1 – Intermediary coating layers

|

Phase |

Type of structure |

Få/Zn composition |

|

1 |

2 |

3 |

|

|

Solid solution of Zn in Fe |

94.8/5.1 |

|

G |

FeZn3; Fe3Zn10;

Fe5Zn21 |

21/79 |

|

|

FeZn7 |

9.07/90.8 |

|

|

FeZn7 + FeZn13 |

8.18/91.7 |

|

|

FeZn13 |

6.1/93.9 |

|

|

Zn |

0.006/99.9 |

Picture 2 – Energy spectrums of

characteristic X-ray radiation:

à) ![]() phase; b) G phase; c)

phase; b) G phase; c) ![]() phases; d)

phases; d) ![]() phase

phase

As is shown above, the more one moves from the coating

surface deep into the stripe (steel base, that is from point 6 to point 1), the

increase in intensity of energy maximums of ferrum and the decrease in energy

maximums of zinc were recorded, which indicated the alteration of zinc and

ferrum quantity in transition from an ![]() phase to a

phase to a ![]() phase.

phase.

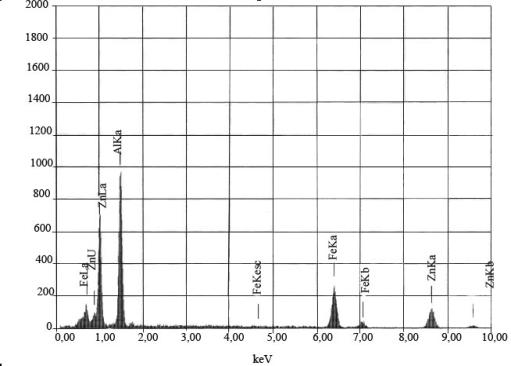

The structure of the aluminum-zinc coating put onto

the strip steel 08kp 0.5mm thick was also investigated. When scanning the

structure of samples in secondary electrons perpendicular to the coating and

obtaining energy spectrums of characteristic radiation in reflected electrons,

the distribution of elements inside the coating was studied (picture 3).

The investigation of aluminum-zinc coatings was done

in three points from the base of metal to the coating periphery. Thus, point 1

corresponds to the spectrum shown in picture 4,a, point 2 is depicted in

picture 4,b and point 3 in picture 4,c. The analysis of energy spectrums of

characteristic X-ray radiation shows that the intensity of energy maximums of

aluminum grows and the energy maximums of ferrum decrease, as one moves away

from the base of metal.

Picture 3 – Energy spectrum in secondary

electrons

Conclusions:

1. Causes of surface

deficiencies in rolled sheet from steel 08kp and 08ps have been experimentally

identified, which permits to recommend measures to reduce surface deficiencies in

the production of metal products with protection coatings.

2. The micro-structure of zinc and aluminum-zinc

coatings has been studied.

3. The characteristics of each layer of the zinc

coating have been obtained by way of measuring energy spectrums of

characteristic X-ray radiation, allowing to identify phases in the structure of

the zinc coating.

4. Experimental results have

permitted to measure the impact of technological regimes of hot galvanization

on the structure of the coating.

Picture 4 – Energy spectrums of characteristic X-ray radiation