Komkov N.M., Kapaeva

S.D.

The East-Kazakhstan State Technical University

Ust-Kamenogorsk, the Kazakhstan Republic

The search of the cutting mechanism

in the time of sharpening in an atmosphere of the water-soluble polymeric

cutting-tool lubricant âï-4

The

leading roles in the economic recovery play a machine-building industry

particularly the metal cutting processes. At the same time much attention is

giving to perfection of the machining operations, productivity and accuracy

increasing, increasing of the cutting tool endurance. The industrial rhythm

needs increasing of quantities and ranges of cutting tools and naturally it

needs increasing of alloying components drain for the hard alloy production.

The increasing of existing cutting tool endurance and durability is very

significant in this situation. The choice of the cutting-tool lubricant may

help to solve this problem.

Today

in machine-building industry generally used the oil and the emulsion

cutting-tool lubricants. The usage of which have an adverse effect to working

conditions and technical conditions of cutting machines parts. Plus it is very

they are difficult-to-make and while using it may take damage to environment.

The

searching in technical literature shows that in influencing on the contact

processes water-soluble polymeric cutting-tool lubricant is as good as the oil

and the emulsion cutting-tool lubricants (CTL). So it is necessary to create

the composition of water-soluble polymeric cutting-tool lubricant(CTL) which in

its cooling abilities will be as good as emulsion CTL and in lubricating

properties will be as good as oil CTL.

The new

CTL must combine with opposite features such as low boundary tension i.e. good

wetting quality, penetrability at the metal flaws and high viscosity for creating

of more pressure in liquid between moving surfaces.

Different

authors searched the water-soluble polymeric CTL in the processes of milling,

glazing, threading, toothing, but not so much in sharpening. Although this

handling type occupies a larger proportion in bulk of today’s metalworking in

machine building.

This

work devoted to increasing of turning tools durability by researching of

water-soluble polymeric CTL influence to turning tools durability and machined

surface quality of constructional and compound steel.

Different

methods are using for the experimental definition of the isothermal curves Ï(h) of penetrating

polymeric film pressure. First researches were done by Deryagin and Kusakov [1]

who used gas bubbles with different radius R0, which emerged to

horizontally placed gentle smooth plate (Picture 1).

Disjoining

pressure of gentle film defined by equation [1] in which is the gas pressure in bubble and P0

is pressure in volumetric fluid phase, which close round the bubble. If we put

P and P0 in [1] we will have:

![]() , ( 1)

, ( 1)

Picture 1 – The bubble method of wetting films

disjoining pressure isothermal curves reception.

Isothermal curves

of disjoining pressure in plane of sliding are belonging from 8.95x102

– 7.77x105 Pascal and film thickness in range of 400-25 A0.

At the breakdown

force estimation we define average normal pressure of liquid between moving

surfaces [2]:

![]() , (2)

, (2)

Where

V-peripheral speed of cutting, m/min

![]() -rotating speed of detail, rad/sec

-rotating speed of detail, rad/sec

![]() - dynamic viscosity

- dynamic viscosity

![]() - kinematic viscosity

- kinematic viscosity

![]() - liquid density

- liquid density

![]() - loading coefficient, which is taken in according to [1]

- loading coefficient, which is taken in according to [1]

Define the liquid pressure between contact

surfaces of detail and cutting tool:

![]()

![]() (3)

(3)

When microcrack size

achieved amount more than 50 0A to disjoining pressure will be added

the pressure in liquid value, and it will increase:

7.77×105+7.77×105+1298025 = 2852025 Pa.

(![]() =10-8 sm. = 10-10 sm.)

=10-8 sm. = 10-10 sm.)

As the

result of the disjoining activity of adsorbed polymeric film and pressure of

the liquid CTL ÂÏ-4, the sharpening process

bypass with lower duty to cutting tool. This help to increase cutting tool

endurance in 1.2-1.4, achieving of the Ra=1.1mkm undulation and

worked pieces dimensional accuracy in high-velocity manufacturing of

constructional and compound steel.

It follows that

singularity of sharpening process course depend from the mechanism of plastic

flow of metal in different mediums.

Study

of the contact processes illustrate the nature of such events as friction, chip

formation, cold-hardening, surface indulation of storages, wear of the cutting

tools. The studies of chip formation process shown, that CTL is reducing the

contact length between chip and cutting tool, essentially, because of the

elastic contact zone reducing. CTL will take effect through the changing of

average friction coefficient and defining the angle of coverage. The using of

CTL which have the ability to penetrate into cutting zone allow to lower the

friction coefficient and to change stress state of metal [3].

With

this object in mind were created a number of new water-soluble polymeric CTL.

Study of which revealed their action mechanism in chip formation and plastic

flow character of machined metal while sharpening. For

the researching of the plastically deformed cutting zone character were made

metallographic samples of processed in different mediums details, and than were

made a metallographic analysis of this samples. For comparative analysis were

selected the standard liquid - CTL ÝÃÒ, which usually using in machine-building production

and the best type of water-soluble polymeric CTL WP-4 (which were created in

working process) [4].

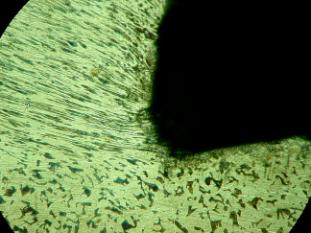

Zone of

the crystal grains (position 1) maximum plastic flow and the character of their

streaming may be defined at the chip root microstructure situated at the

picture 2.

1 2 ψ

![]()

![]()

![]()

Picture 2 – the ñòàëü 20 chip root microstructure un CTL ÝÃÒ medium

The

ranges of deformed metal crystal grains laying at an angle of ψ to the plane of sliding and nearly directly from

facial layer. Such order of the deformed metal crystal gains cause the hard

surfacing and increasing of micro-hardness of chip and processed detail facial

layer. Which in its turn cause the increasing of the cutting tool wear.

The

process which is visible on the picture is the process of metal tearing from

cut surface by cutter. This process cause chatter marks at the processed

surface.(Picture 2, position 2). As a result the processed surface indulation

appear. The value of this indulation in the CTL ÝÃÒ medium situated at the graph of indulation as a

function of cutting speed(Picture 3).

Picture 3 – The

processed detail surface finish dependence of tool back-surface(h3) wear value

in finish sharpening of the ñòàëü 20 by

carbide-faced tool T15K6.

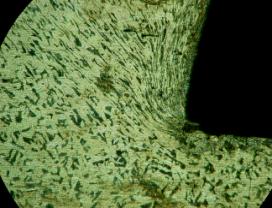

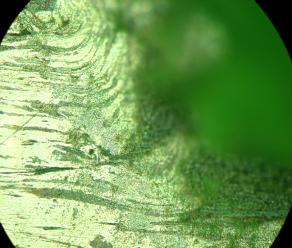

The researching of the chip root microstructure

which was processed in the medium of the CTL ÂÏ -4(Picture 4) has show following results:

2 ψ 1![]()

![]()

![]()

Picture 4 – the ñòàëü 20 chip root microstructure in water-soluble

polymeric CTL ÂÏ-4 medium

At the

micrography of the metallographic sample which has been processed in the medium

of the CTL ÂÏ-4 we can see singularity of

chip deformed crystal gains order, their defined form and orientation. The

value of angle is smaller and it proves that value of the frictional force

lower under the effect of polymeric interfacial film CTL ÂÏ-4. The strips of deformed zones of chip metal crystal

gains parallelism (picture 4, position 1) while saving the constancy of texture

angle, testifying about absence of burst layer secondary deformation. The

effect of which cause the increasing of chip micro-hardness and abrasive wear

of cutting tool. This factor explain the difference of surfaces cold hardening

degree, which were processed in different mediums(Picture 5).

V, m/min

1 - without CTL; 2

- CTL ÝÃÒ;3 – CTL ÂÏ-4.

Picture 5 – the

work-hardening degree(H) dependence of cutting speed(V) in finish sharpening

process.

Also at

the micrograph of metal chip root which has been processed in the CTL WP-4

medium was marked the character of facial layer and indulation(picture 4,position

2). Also at the micrograph evidently viewed decreasing of the indulance lugs

height.

The

action mechanism of water-soluble polymeric CTL ÂÏ-4 (Picture 6) consist in appearing of the disjoining force Pp,

resulting of which and Np fit in vector with sliding force Pτ.

This involves to total force(resulting) increasing.

![]() (4)

(4)

This resulting

force exceed the yield limit of the processing material, and then happen its

destruction (Picture 7). Intercrystalline bond breaking of processing metal is

affected by adsorbed polymeric film of CTL ÂÏ-4 and by the

pressure of liquid. It cause the disjoining effect at the cutting zone i.e. it

cause the Rebinder effect.

So it allow to make

such conclusion that the CTL mechanism depend of chemical composition and of

physical features of liquid with water-soluble polymers.

The CTL created at

the base of water-soluble polymers leads to thermal exchange increasing,

because of high thermal capacity of water which exist copiously in CTL

composition. The increasing of the cutting tool hardness and its load drop

caused by decreasing of temperature in contact zone. It is the first cutting

mechanism.

The decreasing of

frictional force and action angle caused by existence of polyatomic alcohols

and surface acting agents at the CTL ÂÏ-4 compositions

which cause the lubricating effect.. It is the second cutting mechanism.

Picture 6 – the

cutting mechanism with using of water-soluble polymeric

CTL ÂÏ-4.

0,0025ìììì![]()

![]()

![]()

![]()

Picture 7 – sliding

surface zone with the scoth forming by adsorb film of polymeric CTL ÂÏ-4 (×2100)

And the

third cutting mechanism – disjoining mechanism – may able because of opposite

features combination in CTL composition. It means two features: The decreased

boundary tension and the increased viscosity. The existing of monoatomic

alcohols, organic acids and sulphates at CTL composition is decreasing the

liquid boundary tension and increasing wetability of contact surfaces. It

creating the ability of liquid penetration to microcracks and promoting to

destruction of processed metal. And the existing of cooling liquid, furcated

high-polymeric chains of water-soluble polymers at CTL composition coupled with

surface acting agents allow to significantly increase the kinematic viscosity

of liquid. It helps to arise the disjoining effect, which cause the Rebinder

effect.

The

cutting mechanism has been recommended as the most efficient mechanism for the

increasing of cutting tool durability.

The list of literature:

1 Deryagin

B.V., Kusakov M.M. “Experimental researching of the surfaces solvation” News of

the Academe of Sciences of the USSR. Gray chemistry. 1937.

¹5. page

1119-1152.

2

Yakushev A.I., Vorontsov L.N., Fedotov N.M. “Interchangeability, standardizing

and technical metrology”. M.:Machine-building.1986.page 350.

3 Kostetskiy

B.I., Nathanson M.E., Berigatskiy A.I. “Mechanical process in boundary

friction”.M.:Science.1972.page 170.

4

Patent ¹17885 of the Kazakhstan Republic. Cutting-Tool Lubricant for mechanical

process of metal/Komkov N.M., Kapaeva S.D.;16.10.06.bull.¹10.page 2.