L.Ya. Melkozerova (EKSTU), L.V.Kamenskikh (EKSTU)

THREE-DIMENSIONAL SIMULATION

AS A NECESSARY SECTION IN TRAINING FUTURE ENGINEERS

Despite the fact

that used during designing

two-dimensional graphics systems allow to solve the problems facing the user quite

successfully, the development of new technologies induces to the use of three-dimensional

simulation in the training process.

Modern CAD system,

including the one used in the training process, the system KOMPAS -3D has quite

effective means of simulation, which allow to develop three-dimensional model of the most complicated parts and assemblage.

Design of three-dimensional model of a part

or assemblage is one of the stage of its making. The area of COMPAS-3D usage is

determined by the major complex of tasks,

solved by it. The tasks include:

·

simulation of the parts with the aim of calculating their geometric and

mass- centring characteristics;

·

simulation of the parts for transferring geometry into calculation clusters;

·

simulation of the parts for transferring geometry into clusters of

developing controlling programs for the equipment with numerical program control;

·

design of isometric views of the parts (for example, for making

catalogs, illustrations for technical documentation).

After design of 3-D

simulation of a part or assemblage, or just during the design, a designer can

get its draft thus escaping the routine creation of the views by means of plain

drawing. If using any CAD system, allowing to calculate and simulate the part

of any complexity, the user has still to make drafts of the part manually or

with the help of some graphics editor, we can hardly talk about complete

automation of designing. We know that

the more complicated the part the more complicated its view is. This means the

harder and longer monitoring and changing, appearing, for example, during the

testing the testing of experimental sample. In some cases it is not enough to change the structure, but it is

necessary to change the details. At the

same time besides editing the drafts one has to bring changes into specification.

This, in turn, brings to the change of lines order in the specification and the

numbers of positions in the assemblage draft. Thus, the change, made in one and

the only document brings to the necessity of reviewing the whole documentation

complex, and this notably decreases the effectiveness of time saving, got due

to the calculations automation. `

This means that CAD system, allowing

just simulate the part, and possibly, gets its draft does not correspond to the

nowadays demand.

For the successful development and

accompanying the documents we need the system that would help the developer

follow corresponding of the assembling part to the drafts (assembling, working)

and specifications.

The very opportunity is wholly presented

by the modern version of COMPAS system. With its help the user can create the

system of interconnected documents: three-dimension model, its drafts, and

specifications.

The model of designed product is

developed with the use of COMPAS-3D –

editor of three-dimension solid-body models.

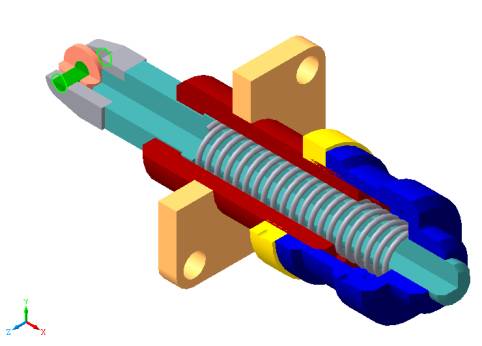

The students were proposed to make three-dimension models of the parts

being the parts of the assemblage and the three-dimension assemblage model

itself (Fig.1).

With the help of draft-design editor

COMPAS-GRAFIK associative views of

the model were constructed. Such views constantly stay in contact with the

models represented in them. Changing the forms, sizes and typology of the model

we change the view in all connected with it views. Due to this the view always corresponds to the model interconnected with

it. Assembling draft on developed model is presented on Fig.2.

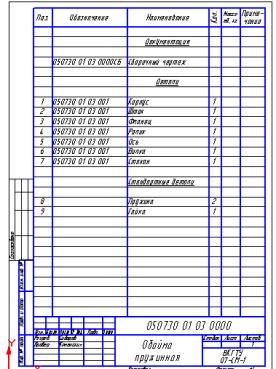

The module of developing the

specifications is now integrated with COMPAS-3D also (Fig. 3), interconnected

with the assembling model as well as with the assembling draft.

The

given technology of design has the following advantages before the traditional

one:

·

high quality of engineering

study the elements, parts, structure components;

·

definite reducing the amount of routine work on making drafts of the same type parts and structure components; concentrating

attention on the essence of the project;

·

perfect quality of graphic work;

·

mastering the basis of principally new perspective technology of

designing things, perfection working skills with PC and COMPAS-GRAFIK system.

Nowadays

there is an urgent issue of intensification of training and research work

supposing modernization of material and technical basis. And first of all, the

computerization of the training processes and designing activity.

Computerization is not that easy issue as it may seem to an inexperienced

person.

In a

technical higher educational institution practically any sub-department needs

the SAD systems. They do not just change old

drawing boards, but also allow to modernize various processes and

interactions, notably decreasing the cycle as a rule extremely high-value

experiments. Their use increases the effectiveness of designing work three to

four times. At the present stage of research activity the introducing of SAD

systems is mostly urgent.